Page 378 - Handbook of Adhesives and Sealants

P. 378

334 Chapter Nine

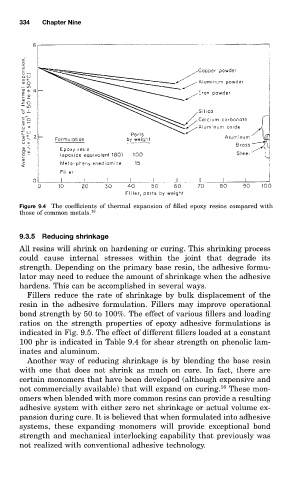

Figure 9.4 The coefficients of thermal expansion of filled epoxy resins compared with

those of common metals. 13

9.3.5 Reducing shrinkage

All resins will shrink on hardening or curing. This shrinking process

could cause internal stresses within the joint that degrade its

strength. Depending on the primary base resin, the adhesive formu-

lator may need to reduce the amount of shrinkage when the adhesive

hardens. This can be accomplished in several ways.

Fillers reduce the rate of shrinkage by bulk displacement of the

resin in the adhesive formulation. Fillers may improve operational

bond strength by 50 to 100%. The effect of various fillers and loading

ratios on the strength properties of epoxy adhesive formulations is

indicated in Fig. 9.5. The effect of different fillers loaded at a constant

100 phr is indicated in Table 9.4 for shear strength on phenolic lam-

inates and aluminum.

Another way of reducing shrinkage is by blending the base resin

with one that does not shrink as much on cure. In fact, there are

certain monomers that have been developed (although expensive and

not commercially available) that will expand on curing. 16 These mon-

omers when blended with more common resins can provide a resulting

adhesive system with either zero net shrinkage or actual volume ex-

pansion during cure. It is believed that when formulated into adhesive

systems, these expanding monomers will provide exceptional bond

strength and mechanical interlocking capability that previously was

not realized with conventional adhesive technology.