Page 381 - Handbook of Adhesives and Sealants

P. 381

Adhesive Composition and Formulation 337

TABLE 9.5 Volume Resistivity of Metals, Conductive Plastics and Various Insulation

Materials at 25 C 20

Specific volume

gravity resistivity

3

(gms/cm ) (ohm cm)

Silver 10.5 1.6 10 6

Copper 8.9 1.8 10 6

Gold 19.3 2.3 10 6

Aluminum 2.7 2.9 10 6

Nickel 8.9 10 10 6

Platinum 21.5 21.5 10 6

Eutectic solders — 20–30 10 6

Best silver-filled inks and coatings — 1 10 4

Best silver-filled epoxy adhesives — 1 10 3

Graphite — 1.3 10 3

Low cost silver-filled epoxy adhesives — 1 10 2

2

Graphite or carbon-filled coatings — 10 to 10

14

Oxide-filled epoxy adhesives 1.5–2.5 10 –10 15

14

Unfilled epoxy adhesives 1.1 10 –10 15

Mica, polystyrene & other best dielectrics — 10 16

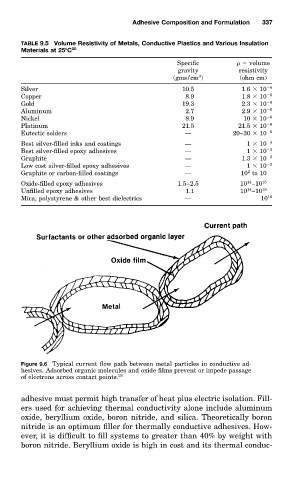

Figure 9.6 Typical current flow path between metal particles in conductive ad-

hesives. Adsorbed organic molecules and oxide films prevent or impede passage

of electrons across contact points. 20

adhesive must permit high transfer of heat plus electric isolation. Fill-

ers used for achieving thermal conductivity alone include aluminum

oxide, beryllium oxide, boron nitride, and silica. Theoretically boron

nitride is an optimum filler for thermally conductive adhesives. How-

ever, it is difficult to fill systems to greater than 40% by weight with

boron nitride. Beryllium oxide is high in cost and its thermal conduc-