Page 427 - Handbook of Adhesives and Sealants

P. 427

Adhesives Families 369

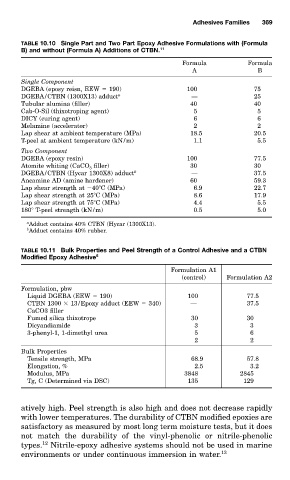

TABLE 10.10 Single Part and Two Part Epoxy Adhesive Formulations with (Formula

B) and without (Formula A) Additions of CTBN. 11

Formula Formula

A B

Single Component

DGEBA (eposy reisn, EEW 190) 100 75

DGEBA/CTBN (1300X13) adduct a — 25

Tubular alumina (filler) 40 40

Cab-O-Sil (thixotroping agent) 5 5

DICY (curing agent) 6 6

Melamine (accelerator) 2 2

Lap shear at ambient temperature (MPa) 18.5 20.5

T-peel at ambient temperature (kN/m) 1.1 5.5

Two Component

DGEBA (epoxy resin) 100 77.5

Atomite whiting (CaCO 3 filler) 30 30

DGEBA/CTBN (Hycar 1300X8) adduct b — 37.5

Ancamine AD (amine hardener) 60 59.3

Lap shear strength at 40 C (MPa) 6.9 22.7

Lap shear strength at 25 C (MPa) 8.6 17.9

Lap shear strength at 75 C (MPa) 4.4 5.5

180 T-peel strength (kN/m) 0.5 5.0

a Adduct contains 40% CTBN (Hycar (1300X13).

b Adduct contains 40% rubber.

TABLE 10.11 Bulk Properties and Peel Strength of a Control Adhesive and a CTBN

Modified Epoxy Adhesive 6

Formulation A1

(control) Formulation A2

Formulation, pbw

Liquid DGEBA (EEW 190) 100 77.5

CTBN 1300 13/Epoxy adduct (EEW 340) — 37.5

CaCO3 filler

Fumed silica thixotrope 30 30

Dicyandiamide 3 3

3-phenyl-1, 1-dimethyl urea 5 6

2 2

Bulk Properties

Tensile strength, MPa 68.9 57.8

Elongation, % 2.5 3.2

Modulus, MPa 3848 2845

Tg, C (Determined via DSC) 135 129

atively high. Peel strength is also high and does not decrease rapidly

with lower temperatures. The durability of CTBN modified epoxies are

satisfactory as measured by most long term moisture tests, but it does

not match the durability of the vinyl-phenolic or nitrile-phenolic

types. 12 Nitrile-epoxy adhesive systems should not be used in marine

environments or under continuous immersion in water. 13