Page 429 - Handbook of Adhesives and Sealants

P. 429

Adhesives Families 371

caulking compounds, encapsulants, potting compounds, conformal

coatings and molding compounds for rubbery parts. 16

Several other approaches have been developed for improving the

toughness and flexibility of epoxy adhesives. Modification of epoxy

resin with alkyl resin is reported as a means of flexibilizing epoxies

for adhesive applications. 17 Modification of epoxy resins through the

direct addition of engineering thermoplastic, such as polysulfone, has

also been proposed to enhance the toughness of epoxy adhesives. 18 It

is likely that the search for toughened epoxy adhesives will continue

in the future.

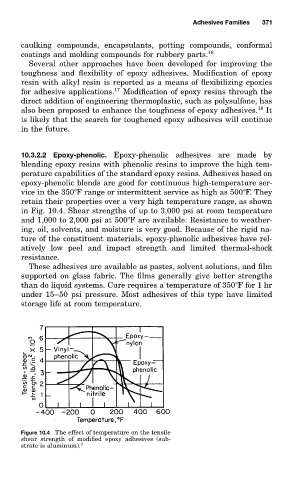

10.3.2.2 Epoxy-phenolic. Epoxy-phenolic adhesives are made by

blending epoxy resins with phenolic resins to improve the high tem-

perature capabilities of the standard epoxy resins. Adhesives based on

epoxy-phenolic blends are good for continuous high-temperature ser-

vice in the 350 F range or intermittent service as high as 500 F. They

retain their properties over a very high temperature range, as shown

in Fig. 10.4. Shear strengths of up to 3,000 psi at room temperature

and 1,000 to 2,000 psi at 500 F are available. Resistance to weather-

ing, oil, solvents, and moisture is very good. Because of the rigid na-

ture of the constituent materials, epoxy-phenolic adhesives have rel-

atively low peel and impact strength and limited thermal-shock

resistance.

These adhesives are available as pastes, solvent solutions, and film

supported on glass fabric. The films generally give better strengths

than do liquid systems. Cure requires a temperature of 350 F for 1 hr

under 15–50 psi pressure. Most adhesives of this type have limited

storage life at room temperature.

Figure 10.4 The effect of temperature on the tensile

shear strength of modified epoxy adhesives (sub-

strate is aluminum). 3