Page 508 - Handbook of Adhesives and Sealants

P. 508

440 Chapter Eleven

Substrate 1

Substrate 2

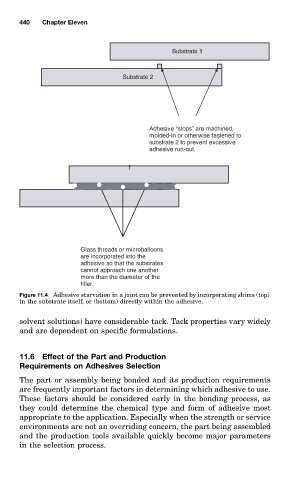

Adhesive “stops” are machined,

molded-in or otherwise fastened to

substrate 2 to prevent excessive

adhesive run-out.

f

Glass threads or microballoons

are incorporated into the

adhesive so that the substrates

cannot approach one another

more than the diameter of the

filler.

Figure 11.4 Adhesive starvation in a joint can be prevented by incorporating shims (top)

in the substrate itself, or (bottom) directly within the adhesive.

solvent solutions) have considerable tack. Tack properties vary widely

and are dependent on specific formulations.

11.6 Effect of the Part and Production

Requirements on Adhesives Selection

The part or assembly being bonded and its production requirements

are frequently important factors in determining which adhesive to use.

These factors should be considered early in the bonding process, as

they could determine the chemical type and form of adhesive most

appropriate to the application. Especially when the strength or service

environments are not an overriding concern, the part being assembled

and the production tools available quickly become major parameters

in the selection process.