Page 55 - Handbook of Adhesives and Sealants

P. 55

An Introduction to Adhesives and Sealants 23

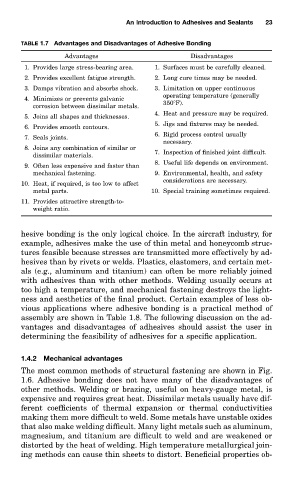

TABLE 1.7 Advantages and Disadvantages of Adhesive Bonding

Advantages Disadvantages

1. Provides large stress-bearing area. 1. Surfaces must be carefully cleaned.

2. Provides excellent fatigue strength. 2. Long cure times may be needed.

3. Damps vibration and absorbs shock. 3. Limitation on upper continuous

operating temperature (generally

4. Minimizes or prevents galvanic

corrosion between dissimilar metals. 350 F).

4. Heat and pressure may be required.

5. Joins all shapes and thicknesses.

5. Jigs and fixtures may be needed.

6. Provides smooth contours.

6. Rigid process control usually

7. Seals joints.

necessary.

8. Joins any combination of similar or

dissimilar materials. 7. Inspection of finished joint difficult.

8. Useful life depends on environment.

9. Often less expensive and faster than

mechanical fastening. 9. Environmental, health, and safety

considerations are necessary.

10. Heat, if required, is too low to affect

metal parts. 10. Special training sometimes required.

11. Provides attractive strength-to-

weight ratio.

hesive bonding is the only logical choice. In the aircraft industry, for

example, adhesives make the use of thin metal and honeycomb struc-

tures feasible because stresses are transmitted more effectively by ad-

hesives than by rivets or welds. Plastics, elastomers, and certain met-

als (e.g., aluminum and titanium) can often be more reliably joined

with adhesives than with other methods. Welding usually occurs at

too high a temperature, and mechanical fastening destroys the light-

ness and aesthetics of the final product. Certain examples of less ob-

vious applications where adhesive bonding is a practical method of

assembly are shown in Table 1.8. The following discussion on the ad-

vantages and disadvantages of adhesives should assist the user in

determining the feasibility of adhesives for a specific application.

1.4.2 Mechanical advantages

The most common methods of structural fastening are shown in Fig.

1.6. Adhesive bonding does not have many of the disadvantages of

other methods. Welding or brazing, useful on heavy-gauge metal, is

expensive and requires great heat. Dissimilar metals usually have dif-

ferent coefficients of thermal expansion or thermal conductivities

making them more difficult to weld. Some metals have unstable oxides

that also make welding difficult. Many light metals such as aluminum,

magnesium, and titanium are difficult to weld and are weakened or

distorted by the heat of welding. High temperature metallurgical join-

ing methods can cause thin sheets to distort. Beneficial properties ob-