Page 557 - Handbook of Adhesives and Sealants

P. 557

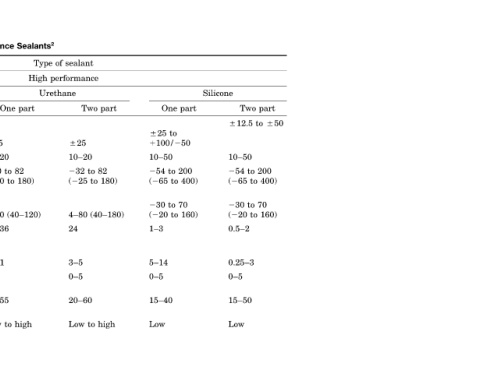

Two part 12.5 to 50 10–50 54 to 200 ( 65 to 400) 30 to 70 ( 20 to 160) 0.5–2 0.25–3 15–50

Silicone 0–5 Low

One part 25 to 100/ 50 10–50 54 to 200 ( 65 to 400) 30 to 70 ( 20 to 160) 1–3 5–14 0–5 15–40 Low

Two part 32 to 82 ( 25 to 180) 4–80 (40–180) Low to high

Type of sealant High performance Urethane 25 10–20 24 3–5 0–5 20–60

Summary of Sealant Properties for Common High Performance Sealants 2

One part ( 40 to 180) 4–50 (40–120) Low to high

25 10–20 40 to 82 12–36 8–21 0–5 30–55

Two part 51 to 82 ( 60 to 180) 4–50 (40–120) 36–48(c) Low to moderate

Polysulfide 25 10–20 7 0–10 20–55

One part 25 10–20 40 to 82 ( 40 to 180) 4–50 (40–120) 24(c) 30–45 8–12 30–55 Low to high

Characteristic Maximum recommended joint movement, percent of Life expectancy, years(a) Service temperature range, Recommended application temperature range, C Cure

TABLE 13.3 joint width C( F) ( F)(b) condition, h(c) Shrinkage, % low temperature

479