Page 74 - Handbook of Adhesives and Sealants

P. 74

42 Chapter One

1.7 General Materials and Processes

This section will describe the most common materials and processes

used for adhesive bonding and sealing. They are described here in the

most general and functional of terms and then will be addressed again

in more detail in later chapters.

1.7.1 Materials used for adhesives and

sealants

Solid surfaces brought into intimate contact rarely stick to one an-

other, but any liquid placed between them will cause some degree of

adhesion. Therefore, almost anything could be used as an adhesive or

sealant. However, the nature of the substrate, its surface chemistry,

the processing method, and the type of the load and service environ-

ment will dictate what material is best to use. The material scientists

have developed many substances of high molecular weight which give

good adhesion and sealing ability to a variety of substrates.

Although adhesives and sealants are often formulated from the

same types of base materials, they are usually ‘‘engineered’’ to have

different properties. Adhesives and sealants are highly formulated

materials with many components. They generally have an organic

base, although there are some mineral-based adhesives that perform

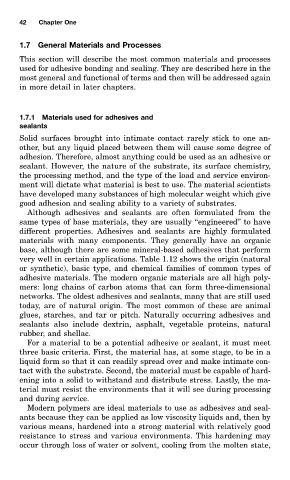

very well in certain applications. Table 1.12 shows the origin (natural

or synthetic), basic type, and chemical families of common types of

adhesive materials. The modern organic materials are all high poly-

mers: long chains of carbon atoms that can form three-dimensional

networks. The oldest adhesives and sealants, many that are still used

today, are of natural origin. The most common of these are animal

glues, starches, and tar or pitch. Naturally occurring adhesives and

sealants also include dextrin, asphalt, vegetable proteins, natural

rubber, and shellac.

For a material to be a potential adhesive or sealant, it must meet

three basic criteria. First, the material has, at some stage, to be in a

liquid form so that it can readily spread over and make intimate con-

tact with the substrate. Second, the material must be capable of hard-

ening into a solid to withstand and distribute stress. Lastly, the ma-

terial must resist the environments that it will see during processing

and during service.

Modern polymers are ideal materials to use as adhesives and seal-

ants because they can be applied as low viscosity liquids and, then by

various means, hardened into a strong material with relatively good

resistance to stress and various environments. This hardening may

occur through loss of water or solvent, cooling from the molten state,