Page 331 - Handbook of Battery Materials

P. 331

11.2 Separators for Lead–Acid Storage Batteries 301

use trichloroethylene as the solvent; it is easy to handle processwise, but as a

chlorinated hydrocarbon it carries environmental risks.

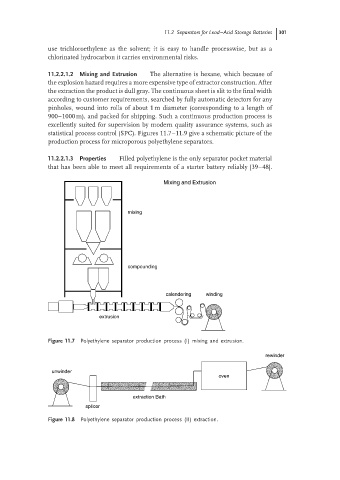

11.2.2.1.2 Mixing and Extrusion The alternative is hexane, which because of

the explosion hazard requires a more expensive type of extractor construction. After

the extraction the product is dull gray. The continuous sheet is slit to the final width

according to customer requirements, searched by fully automatic detectors for any

pinholes, wound into rolls of about 1 m diameter (corresponding to a length of

900–1000 m), and packed for shipping. Such a continuous production process is

excellently suited for supervision by modern quality assurance systems, such as

statistical process control (SPC). Figures 11.7–11.9 give a schematic picture of the

production process for microporous polyethylene separators.

11.2.2.1.3 Properties Filled polyethylene is the only separator pocket material

that has been able to meet all requirements of a starter battery reliably [39–48].

Mixing and Extrusion

mixing

compounding

calendering winding

extrusion

Figure 11.7 Polyethylene separator production process (I) mixing and extrusion.

rewinder

unwinder

oven

extraction Bath

splicer

Figure 11.8 Polyethylene separator production process (II) extraction.