Page 332 - Handbook of Battery Materials

P. 332

302 11 Separators

unwinder splicer calender pinhole detector slitting rewinder

Figure 11.9 Polyethylene separator production process (III) slitting.

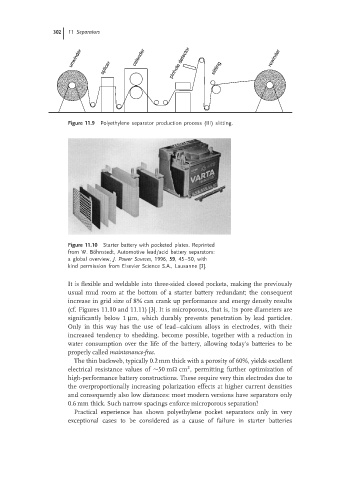

Figure 11.10 Starter battery with pocketed plates. Reprinted

from W. B¨ohnstedt, Automotive lead/acid battery separators:

a global overview, J. Power Sources, 1996, 59, 45–50, with

kind permission from Elsevier Science S.A., Lausanne [3].

It is flexible and weldable into three-sided closed pockets, making the previously

usual mud room at the bottom of a starter battery redundant; the consequent

increase in grid size of 8% can crank up performance and energy density results

(cf. Figures 11.10 and 11.11) [3]. It is microporous, that is, its pore diameters are

significantly below 1 µm, which durably prevents penetration by lead particles.

Only in this way has the use of lead–calcium alloys in electrodes, with their

increased tendency to shedding, become possible, together with a reduction in

water consumption over the life of the battery, allowing today’s batteries to be

properly called maintenance-free.

The thin backweb, typically 0.2 mm thick with a porosity of 60%, yields excellent

2

electrical resistance values of ∼50 m cm , permitting further optimization of

high-performance battery constructions. These require very thin electrodes due to

the overproportionally increasing polarization effects at higher current densities

and consequently also low distances: most modern versions have separators only

0.6 mm thick. Such narrow spacings enforce microporous separation!

Practical experience has shown polyethylene pocket separators only in very

exceptional cases to be considered as a cause of failure in starter batteries