Page 275 - Handbook of Electrical Engineering

P. 275

260 HANDBOOK OF ELECTRICAL ENGINEERING

10.6 TYPES OF PROTECTION FOR INGRESS OF WATER AND SOLID

PARTICLES

10.6.1 European Practice

Whether equipment is certified for hazardous area use or not, it needs to be suitable for the daily

environment in which it will be installed. The description of the environment as ‘daily’ takes account

of human interaction with the equipment. For example motors may be installed in a normally dry

location either indoors or outdoors, but the plant personnel may regularly hose down the location with

water. Equipment may be installed in a plant room that is protected against fire by water spray heads.

IEC60529 is the most commonly used standard for defining the ‘degree of ingress protection’

for both liquids and particles. (IEC60694, 1996 version, also describes the coding with particular

emphasis on switchgear and controlgear, and IEC60034 part 5 to rotating electrical machines.) The

most familiar form of the ‘IP’ code is described herein. The 1989 and later versions of the standard

do have some additional refinements for special situations.

The basic code has six digits of the form, I P n m a s. The first two signify ‘Ingress Protection’

and do not change. The third digit n, refers to ingress by particles. The fourth digit, m, refers to

ingress by liquids. The digits n and m range from 1 to 9, the higher the number the more protection is

provided. Some combinations of n and m have a generally accepted connotation. The fifth digit a, is

called an ‘additional letter’ and relates to the diameter and length of across probes that can gain access

to parts that are a hazard in terms of electric shock. The sixth digit s, is called a ‘supplementary letter’,

and relates to high voltage, rotating and stationary dangerous internal parts. It also relates to extra

protection requirements for specified weather conditions. The fifth and sixth letters are often omitted.

Note: Large particles should be read as to include human hands, fingers, insects, tools and foreign

bodies.

The familiar form is that which is well understood by manufacturers, suppliers and their

customers.

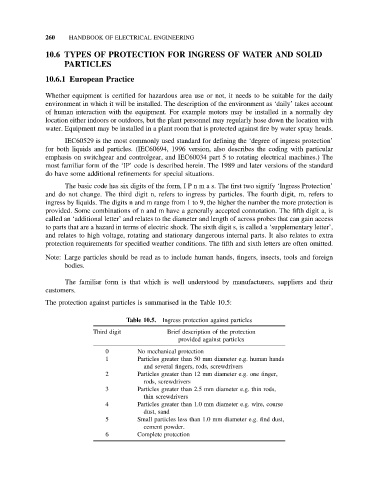

The protection against particles is summarised in the Table 10.5:

Table 10.5. Ingress protection against particles

Third digit Brief description of the protection

provided against particles

0 No mechanical protection

1 Particles greater than 50 mm diameter e.g. human hands

and several fingers, rods, screwdrivers

2 Particles greater than 12 mm diameter e.g. one finger,

rods, screwdrivers

3 Particles greater than 2.5 mm diameter e.g. thin rods,

thin screwdrivers

4 Particles greater than 1.0 mm diameter e.g. wire, course

dust, sand

5 Small particles less than 1.0 mm diameter e.g. find dust,

cement powder.

6 Complete protection