Page 53 - Handbook of Energy Engineering Calculations

P. 53

way of estimating air and flue-gas quantities generated in boiler and heater

operations when the ultimate fuel analysis is not available and all the

engineer is interested in is good estimates. Air and flue-gas quantities

determined may be used to calculate the size of fans, ducts, stacks, etc.

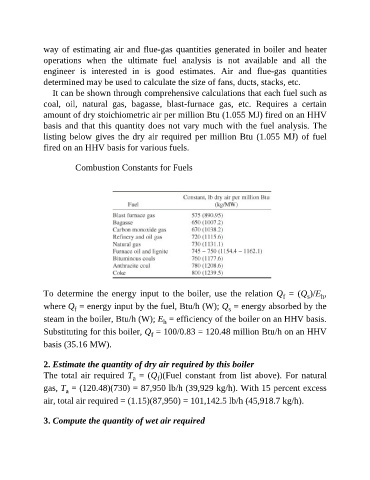

It can be shown through comprehensive calculations that each fuel such as

coal, oil, natural gas, bagasse, blast-furnace gas, etc. Requires a certain

amount of dry stoichiometric air per million Btu (1.055 MJ) fired on an HHV

basis and that this quantity does not vary much with the fuel analysis. The

listing below gives the dry air required per million Btu (1.055 MJ) of fuel

fired on an HHV basis for various fuels.

Combustion Constants for Fuels

To determine the energy input to the boiler, use the relation Q = (Q )/E ,

h

s

f

where Q = energy input by the fuel, Btu/h (W); Q = energy absorbed by the

s

f

steam in the boiler, Btu/h (W); E = efficiency of the boiler on an HHV basis.

h

Substituting for this boiler, Q = 100/0.83 = 120.48 million Btu/h on an HHV

f

basis (35.16 MW).

2. Estimate the quantity of dry air required by this boiler

The total air required T = (Q )(Fuel constant from list above). For natural

a

f

gas, T = (120.48)(730) = 87,950 lb/h (39,929 kg/h). With 15 percent excess

a

air, total air required = (1.15)(87,950) = 101,142.5 lb/h (45,918.7 kg/h).

3. Compute the quantity of wet air required