Page 111 - Handbook of Plastics Technologies

P. 111

THERMOPLASTICS

THERMOPLASTICS 2.51

may build up on the cylinder wall, yielding parts with black marks. Residual stresses may

be reduced by higher mold temperatures or by annealing. Extrusion and blow-molding

grades of polysulfones are higher molecular weight, with blow molding melt temperatures

in the range of 300 to 360°C and mold temperatures between 70 and 95°C.

The good heat resistance and electrical properties of polysulfones allows them to be

used in applications such as circuit boards and TV components. 352 Chemical and heat re-

sistance are important properties for automotive applications. Hair dryer components can

also be made from polysulfones. Polysulfones find application in ignition components and

structural foams. 353 Another important market for polysulfones is microwave cook-

ware. 354

2.2.27.1 Polyaryl Sulfone (PAS). This polymer differs from the other polysulfones in

the lack of any aliphatic groups in the chain. The lack of aliphatic groups gives this poly-

mer excellent oxidative stability, as the aliphatic groups are more susceptible to oxidative

degradation. 355 Polyaryl sulfones are stiff, strong, and tough polymers with very good

chemical resistance. Most fuels, lubricants, cleaning agents, and hydraulic fluids will not

affect the polymer. 356 However, methylene chloride, dimethyl acetamide, and dimethyl

formamide will dissolve the polymer. 357 The glass transition temperature of these poly-

mers is about 210°C, with a heat deflection temperature of 205°C at 1.82 MPa. 358 PAS

also has good hydrolytic stability. Polyarylsulfone is available in filled and reinforced

grades as well as both opaque and transparent versions. 359 This polymer finds application

in electrical applications for motor parts, connectors, and lamp housings. 360

The polymer can be injection molded, provided the cylinder and nozzle are capable of

reaching 425°C. 361 It may also be extruded. The polymer should be dried prior to process-

ing. Injection molding barrel temperatures should be 270 to 360°C at the rear, 295 to

390°C in the middle, and 300 to 395°C at the front. 362

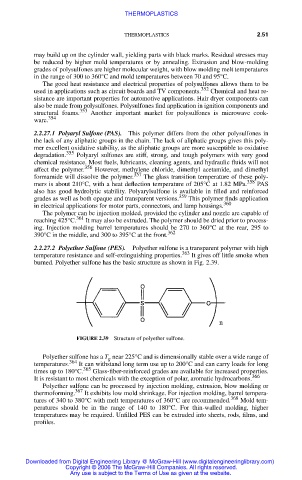

2.2.27.2 Polyether Sulfone (PES). Polyether sulfone is a transparent polymer with high

temperature resistance and self-extinguishing properties. 363 It gives off little smoke when

burned. Polyether sulfone has the basic structure as shown in Fig. 2.39.

FIGURE 2.39 Structure of polyether sulfone.

Polyether sulfone has a T near 225°C and is dimensionally stable over a wide range of

g

364

temperatures. It can withstand long term use up to 200°C and can carry loads for long

365

times up to 180°C. Glass-fiber-reinforced grades are available for increased properties.

366

It is resistant to most chemicals with the exception of polar, aromatic hydrocarbons.

Polyether sulfone can be processed by injection molding, extrusion, blow molding or

367

thermoforming. It exhibits low mold shrinkage. For injection molding, barrel tempera-

368

tures of 340 to 380°C with melt temperatures of 360°C are recommended. Mold tem-

peratures should be in the range of 140 to 180°C. For thin-walled molding, higher

temperatures may be required. Unfilled PES can be extruded into sheets, rods, films, and

profiles.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.