Page 134 - Handbook of Plastics Technologies

P. 134

THERMOSETS

3.4 CHAPTER 3

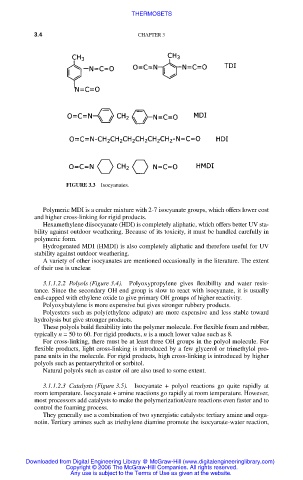

FIGURE 3.3 Isocyanates.

Polymeric MDI is a cruder mixture with 2-7 isocyanate groups, which offers lower cost

and higher cross-linking for rigid products.

Hexamethylene diisocyanate (HDI) is completely aliphatic, which offers better UV sta-

bility against outdoor weathering. Because of its toxicity, it must be handled carefully in

polymeric form.

Hydrogenated MDI (HMDI) is also completely aliphatic and therefore useful for UV

stability against outdoor weathering.

A variety of other isocyanates are mentioned occasionally in the literature. The extent

of their use is unclear.

3.1.1.2.2 Polyols (Figure 3.4). Polyoxypropylene gives flexibility and water resis-

tance. Since the secondary OH end group is slow to react with isocyanate, it is usually

end-capped with ethylene oxide to give primary OH groups of higher reactivity.

Polyoxybutylene is more expensive but gives stronger rubbery products.

Polyesters such as poly(ethylene adipate) are more expensive and less stable toward

hydrolysis but give stronger products.

These polyols build flexibility into the polymer molecule. For flexible foam and rubber,

typically n = 50 to 60. For rigid products, n is a much lower value such as 8.

For cross-linking, there must be at least three OH groups in the polyol molecule. For

flexible products, light cross-linking is introduced by a few glycerol or trimethylol pro-

pane units in the molecule. For rigid products, high cross-linking is introduced by higher

polyols such as pentaerythritol or sorbitol.

Natural polyols such as castor oil are also used to some extent.

3.1.1.2.3 Catalysts (Figure 3.5). Isocyanate + polyol reactions go quite rapidly at

room temperature. Isocyanate + amine reactions go rapidly at room temperature. However,

most processors add catalysts to make the polymerization/cure reactions even faster and to

control the foaming process.

They generally use a combination of two synergistic catalysts: tertiary amine and orga-

notin. Tertiary amines such as triethylene diamine promote the isocyanate-water reaction,

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.