Page 135 - Handbook of Plastics Technologies

P. 135

THERMOSETS

THERMOSETS 3.5

FIGURE 3.4 Polyols.

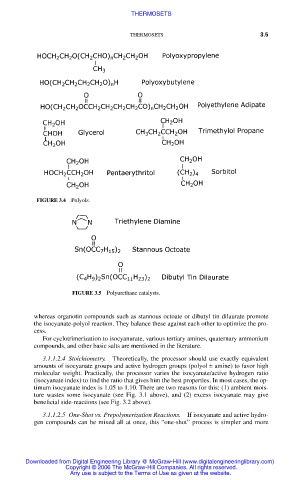

FIGURE 3.5 Polyurethane catalysts.

whereas organotin compounds such as stannous octoate or dibutyl tin dilaurate promote

the isocyanate-polyol reaction. They balance these against each other to optimize the pro-

cess.

For cyclotrimerization to isocyanurate, various tertiary amines, quaternary ammonium

compounds, and other basic salts are mentioned in the literature.

3.1.1.2.4 Stoichiometry. Theoretically, the processor should use exactly equivalent

amounts of isocyanate groups and active hydrogen groups (polyol ± amine) to favor high

molecular weight. Practically, the processor varies the isocyanate/active hydrogen ratio

(isocyanate index) to find the ratio that gives him the best properties. In most cases, the op-

timum isocyanate index is 1.05 to 1.10. There are two reasons for this: (1) ambient mois-

ture wastes some isocyanate (see Fig. 3.1 above), and (2) excess isocyanate may give

beneficial side-reactions (see Fig. 3.2 above).

3.1.1.2.5 One-Shot vs. Prepolymerization Reactions. If isocyanate and active hydro-

gen compounds can be mixed all at once, this “one-shot” process is simpler and more

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.