Page 16 - Handbook of Plastics Technologies

P. 16

INTRODUCTION TO POLYMERS AND PLASTICS

1.2 CHAPTER 1

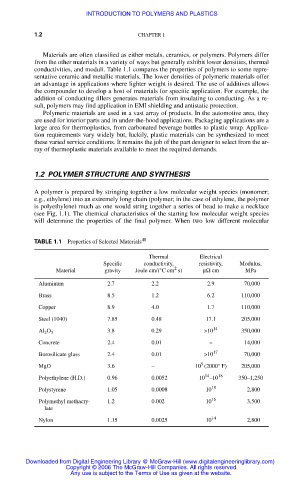

Materials are often classified as either metals, ceramics, or polymers. Polymers differ

from the other materials in a variety of ways but generally exhibit lower densities, thermal

conductivities, and moduli. Table 1.1 compares the properties of polymers to some repre-

sentative ceramic and metallic materials. The lower densities of polymeric materials offer

an advantage in applications where lighter weight is desired. The use of additives allows

the compounder to develop a host of materials for specific application. For example, the

addition of conducting fillers generates materials from insulating to conducting. As a re-

sult, polymers may find application in EMI shielding and antistatic protection.

Polymeric materials are used in a vast array of products. In the automotive area, they

are used for interior parts and in under-the-hood applications. Packaging applications are a

large area for thermoplastics, from carbonated beverage bottles to plastic wrap. Applica-

tion requirements vary widely but, luckily, plastic materials can be synthesized to meet

these varied service conditions. It remains the job of the part designer to select from the ar-

ray of thermoplastic materials available to meet the required demands.

1.2 POLYMER STRUCTURE AND SYNTHESIS

A polymer is prepared by stringing together a low molecular weight species (monomer;

e.g., ethylene) into an extremely long chain (polymer; in the case of ethylene, the polymer

is polyethylene) much as one would string together a series of bead to make a necklace

(see Fig. 1.1). The chemical characteristics of the starting low molecular weight species

will determine the properties of the final polymer. When two low different molecular

TABLE 1.1 Properties of Selected Materials 48

Thermal Electrical

Specific conductivity, resistivity, Modulus,

2

Material gravity Joule cm/(°C cm s) µΩ cm MPa

Aluminum 2.7 2.2 2.9 70,000

Brass 8.5 1.2 6.2 110,000

Copper 8.9 4.0 1.7 110,000

Steel (1040) 7.85 0.48 17.1 205,000

Al O 3.8 0.29 >10 14 350,000

2 3

Concrete 2.4 0.01 – 14,000

Borosilicate glass 2.4 0.01 >10 17 70,000

5

MgO 3.6 – 10 (2000° F) 205,000

14

Polyethylene (H.D.) 0.96 0.0052 10 –10 18 350–1,250

Polystyrene 1.05 0.0008 10 18 2,800

Polymethyl methacry- 1.2 0.002 10 16 3,500

late

Nylon 1.15 0.0025 10 14 2,800

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.