Page 219 - Handbook of Plastics Technologies

P. 219

ELASTOMERS

ELASTOMERS 4.11

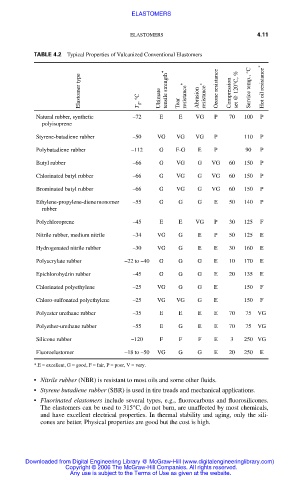

TABLE 4.2 Typical Properties of Vulcanized Conventional Elastomers

Elastomer type T g , °C Ultimate tensile strength * Tear resistance * Abrasion * resistance Ozone resistance Compression set @ 120°C, % Service temp., °C Hot oil resistance *

Natural rubber, synthetic –72 E E VG P 70 100 P

polyisoprene

Styrene-butadiene rubber –50 VG VG VG P 110 P

Polybutadiene rubber –112 G F-G E P 90 P

Butyl rubber –66 G VG G VG 60 150 P

Chlorinated butyl rubber –66 G VG G VG 60 150 P

Brominated butyl rubber –66 G VG G VG 60 150 P

Ethylene-propylene-diene monomer –55 G G G E 50 140 P

rubber

Polychloroprene –45 E E VG P 30 125 F

Nitrile rubber, medium nitrile –34 VG G E P 50 125 E

Hydrogenated nitrile rubber –30 VG G E E 30 160 E

Polyacrylate rubber –22 to –40 G G G E 10 170 E

Epichlorohydrin rubber –45 G G G E 20 135 E

Chlorinated polyethylene –25 VG G G E 150 F

Chloro-sulfonated polyethylene –25 VG VG G E 150 F

Polyester urethane rubber –35 E E E E 70 75 VG

Polyether-urethane rubber –55 E G E E 70 75 VG

Silicone rubber –120 F F F E 3 250 VG

Fluoroelastomer –18 to –50 VG G G E 20 250 E

*.E = excellent, G = good, F = fair, P = poor, V = very.

• Nitrile rubber (NBR) is resistant to most oils and some other fluids.

• Styrene butadiene rubber (SBR) is used in tire treads and mechanical applications.

• Fluorinated elastomers include several types, e.g., fluorocarbons and fluorosilicones.

The elastomers can be used to 315°C, do not burn, are unaffected by most chemicals,

and have excellent electrical properties. In thermal stability and aging, only the sili-

cones are better. Physical properties are good but the cost is high.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.