Page 318 - Handbook of Plastics Technologies

P. 318

ELASTOMERS

4.110 CHAPTER 4

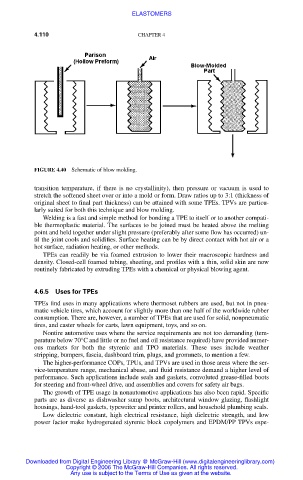

FIGURE 4.40 Schematic of blow molding.

transition temperature, if there is no crystallinity), then pressure or vacuum is used to

stretch the softened sheet over or into a mold or form. Draw ratios up to 3:1 (thickness of

original sheet to final part thickness) can be attained with some TPEs. TPVs are particu-

larly suited for both this technique and blow molding.

Welding is a fast and simple method for bonding a TPE to itself or to another compati-

ble thermoplastic material. The surfaces to be joined must be heated above the melting

point and held together under slight pressure (preferably after some flow has occurred) un-

til the joint cools and solidifies. Surface heating can be by direct contact with hot air or a

hot surface, radiation heating, or other methods.

TPEs can readily be via foamed extrusion to lower their macroscopic hardness and

density. Closed-cell foamed tubing, sheeting, and profiles with a thin, solid skin are now

routinely fabricated by extruding TPEs with a chemical or physical blowing agent.

4.6.5 Uses for TPEs

TPEs find uses in many applications where thermoset rubbers are used, but not in pneu-

matic vehicle tires, which account for slightly more than one half of the worldwide rubber

consumption. There are, however, a number of TPEs that are used for solid, nonpneumatic

tires, and caster wheels for carts, lawn equipment, toys, and so on.

Nontire automotive uses where the service requirements are not too demanding (tem-

perature below 70°C and little or no fuel and oil resistance required) have provided numer-

ous markets for both the styrenic and TPO materials. These uses include weather

stripping, bumpers, fascia, dashboard trim, plugs, and grommets, to mention a few.

The higher-performance COPs, TPUs, and TPVs are used in those areas where the ser-

vice-temperature range, mechanical abuse, and fluid resistance demand a higher level of

performance. Such applications include seals and gaskets, convoluted grease-filled boots

for steering and front-wheel drive, and assemblies and covers for safety air bags.

The growth of TPE usage in nonautomotive applications has also been rapid. Specific

parts are as diverse as dishwasher sump boots, architectural window glazing, flashlight

housings, hand-tool gaskets, typewriter and printer rollers, and household plumbing seals.

Low dielectric constant, high electrical resistance, high dielectric strength, and low

power factor make hydrogenated styrenic block copolymers and EPDM/PP TPVs espe-

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.