Page 357 - Handbook of Plastics Technologies

P. 357

PLASTICS ADDITIVES

PLASTICS ADDITIVES 5.37

• Metal stearates (Ca, Zn, Mg)

• Paraffin waxes (MW 300-600)

• Polyethylene waxes (MW 1,000-10,000)

• Fatty alcohols and acids

• Lecithin

• Organic phosphate esters

• Fluoropolymers

• Silicones

• Antiblocking agents (diatomaceous earth, talc, calcium carbonate, silica, silicates)

5.5.5 Major Use in Polymers

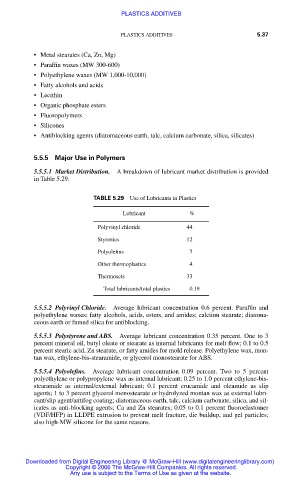

5.5.5.1 Market Distribution. A breakdown of lubricant market distribution is provided

in Table 5.29.

TABLE 5.29 Use of Lubricants in Plastics

Lubricant %

Polyvinyl chloride 44

Styrenics 12

Polyolefins 7

Other thermoplastics 4

Thermosets 33

Total lubricants/total plastics 0.19

5.5.5.2 Polyvinyl Chloride. Average lubricant concentration 0.6 percent. Paraffin and

polyethylene waxes; fatty alcohols, acids, esters, and amides; calcium stearate; diatoma-

ceous earth or fumed silica for antiblocking.

5.5.5.3 Polystyrene and ABS. Average lubricant concentration 0.35 percent. One to 3

percent mineral oil, butyl oleate or stearate as internal lubricants for melt flow; 0.1 to 0.5

percent stearic acid, Zn stearate, or fatty amides for mold release. Polyethylene wax, mon-

tan wax, ethylene-bis-stearamide, or glycerol monostearate for ABS.

5.5.5.4 Polyolefins. Average lubricant concentration 0.09 percent. Two to 5 percent

polyethylene or polypropylene wax as internal lubricant; 0.25 to 1.0 percent ethylene-bis-

stearamide as internal/external lubricant; 0.1 percent erucamide and oleamide as slip

agents; 1 to 3 percent glycerol monostearate or hydrolyzed montan wax as external lubri-

cant/slip agent/antifog coating; diatomaceous earth, talc, calcium carbonate, silica, and sil-

icates as anti-blocking agents; Ca and Zn stearates; 0.05 to 0.1 percent fluoroelastomer

(VDF/HFP) in LLDPE extrusion to prevent melt fracture, die buildup, and gel particles;

also high-MW silicone for the same reasons.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.