Page 369 - Handbook of Plastics Technologies

P. 369

PLASTICS ADDITIVES

PLASTICS ADDITIVES 5.49

5.8.6.3 Color Concentrate (Masterbatch). Expert compounders disperse colorants at

20 to 60 percent concentration in a carrier polymer, using high shear to break down ag-

glomerates and produce uniform dispersion of maximum coloring efficiency. This color

concentrate is used by processors, simply blending it with virgin (natural color) resin (“let-

down with natural”). Typical ratios of concentrate/natural are 1/20 to 1/100. This tech-

nique is low in cost, does not create inventory problems, and is most commonly used with

commodity resins.

5.8.6.4 Liquid Color. The colorant is predispersed in a liquid carrier, hopefully compat-

ible with the resin. It is metered into the base of the hopper or the beginning of the screw

in extrusion or injection molding and blends uniformly with the resin by the time it

reaches the exit from the screw. Although originally billed as a universal technique, it has

rather found applications in certain processes where it is the optimum technique.

5.8.6.5 Color Infusion. This immerses the finished plastic product in a hot aqueous dis-

persion of colorant + dispersant. In several minutes, the color diffuses into the plastic

product, giving it permanent coloration. The length of time determines the depth of the

color.

5.8.7 Special Colorants

Fluorescent colors are used to produce brighter reds and yellows. Phosphorescent colors

are used to produce brighter yellows-greens-blues. Pearlescent colors combine internal

and external reflections; they are made by techniques such as coating titanium dioxide on

mica.

Metallic flakes are added to colorants to give them a metallic sheen. Aluminum flakes

give a silvery sheen and also improve UV stability and impermeability. Bronze flakes can

be formulated into a range of colors from green to red to gold.

5.8.8 Fluorescent Whiteners

Most polymers tend to form conjugated unsaturation during aging, absorbing blue light

from the visible spectrum and therefore turning somewhat yellow. One way to mask this is

to add fluorescent whiteners.

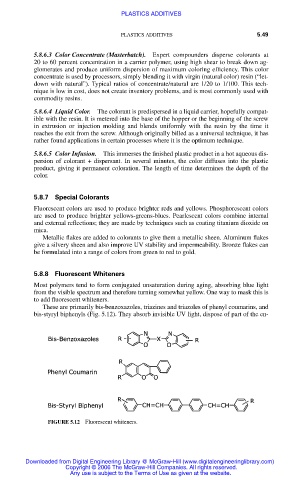

These are primarily bis-benzoxazoles, triazines and triazoles of phenyl coumarins, and

bis-styryl biphenyls (Fig. 5.12). They absorb invisible UV light, dispose of part of the en-

FIGURE 5.12 Fluorescent whiteners.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.