Page 38 - Handbook of Plastics Technologies

P. 38

INTRODUCTION TO POLYMERS AND PLASTICS

1.24 CHAPTER 1

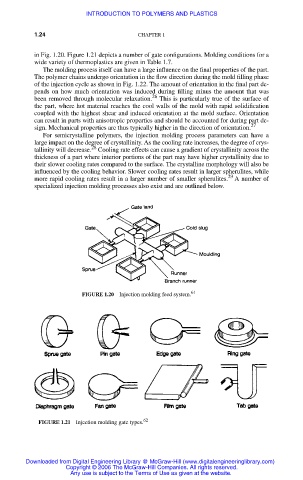

in Fig. 1.20. Figure 1.21 depicts a number of gate configurations. Molding conditions for a

wide variety of thermoplastics are given in Table 1.7.

The molding process itself can have a large influence on the final properties of the part.

The polymer chains undergo orientation in the flow direction during the mold filling phase

of the injection cycle as shown in Fig. 1.22. The amount of orientation in the final part de-

pends on how much orientation was induced during filling minus the amount that was

26

been removed through molecular relaxation. This is particularly true of the surface of

the part, where hot material reaches the cool walls of the mold with rapid solidification

coupled with the highest shear and induced orientation at the mold surface. Orientation

can result in parts with anisotropic properties and should be accounted for during part de-

sign. Mechanical properties are thus typically higher in the direction of orientation. 27

For semicrystalline polymers, the injection molding process parameters can have a

large impact on the degree of crystallinity. As the cooling rate increases, the degree of crys-

28

tallinity will decrease. Cooling rate effects can cause a gradient of crystallinity across the

thickness of a part where interior portions of the part may have higher crystallinity due to

their slower cooling rates compared to the surface. The crystalline morphology will also be

influenced by the cooling behavior. Slower cooling rates result in larger spherulites, while

29

more rapid cooling rates result in a larger number of smaller spherulites. A number of

specialized injection molding processes also exist and are outlined below.

FIGURE 1.20 Injection molding feed system. 61

FIGURE 1.21 Injection molding gate types. 62

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.