Page 36 - Handbook of Plastics Technologies

P. 36

INTRODUCTION TO POLYMERS AND PLASTICS

1.22 CHAPTER 1

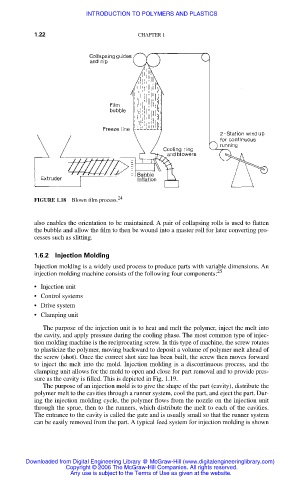

FIGURE 1.18 Blown film process. 24

also enables the orientation to be maintained. A pair of collapsing rolls is used to flatten

the bubble and allow the film to then be wound into a master roll for later converting pro-

cesses such as slitting.

1.6.2 Injection Molding

Injection molding is a widely used process to produce parts with variable dimensions. An

25

injection molding machine consists of the following four components:

• Injection unit

• Control systems

• Drive system

• Clamping unit

The purpose of the injection unit is to heat and melt the polymer, inject the melt into

the cavity, and apply pressure during the cooling phase. The most common type of injec-

tion molding machine is the reciprocating screw. In this type of machine, the screw rotates

to plasticize the polymer, moving backward to deposit a volume of polymer melt ahead of

the screw (shot). Once the correct shot size has been built, the screw then moves forward

to inject the melt into the mold. Injection molding is a discontinuous process, and the

clamping unit allows for the mold to open and close for part removal and to provide pres-

sure as the cavity is filled. This is depicted in Fig. 1.19.

The purpose of an injection mold is to give the shape of the part (cavity), distribute the

polymer melt to the cavities through a runner system, cool the part, and eject the part. Dur-

ing the injection molding cycle, the polymer flows from the nozzle on the injection unit

through the sprue, then to the runners, which distribute the melt to each of the cavities.

The entrance to the cavity is called the gate and is usually small so that the runner system

can be easily removed from the part. A typical feed system for injection molding is shown

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.