Page 31 - Handbook of Plastics Technologies

P. 31

INTRODUCTION TO POLYMERS AND PLASTICS

INTRODUCTION TO POLYMERS AND PLASTICS 1.17

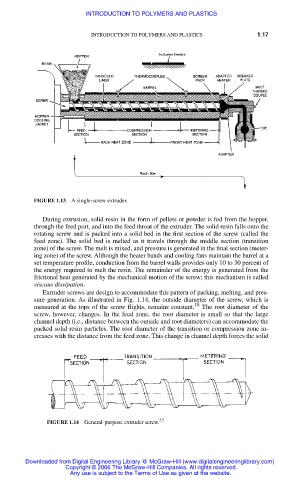

FIGURE 1.13 A single-screw extruder.

During extrusion, solid resin in the form of pellets or powder is fed from the hopper,

through the feed port, and into the feed throat of the extruder. The solid resin falls onto the

rotating screw and is packed into a solid bed in the first section of the screw (called the

feed zone). The solid bed is melted as it travels through the middle section (transition

zone) of the screw. The melt is mixed, and pressure is generated in the final section (meter-

ing zone) of the screw. Although the heater bands and cooling fans maintain the barrel at a

set temperature profile, conduction from the barrel walls provides only 10 to 30 percent of

the energy required to melt the resin. The remainder of the energy is generated from the

frictional heat generated by the mechanical motion of the screw; this mechanism is called

viscous dissipation.

Extruder screws are design to accommodate this pattern of packing, melting, and pres-

sure generation. As illustrated in Fig. 1.14, the outside diameter of the screw, which is

18

measured at the tops of the screw flights, remains constant. The root diameter of the

screw, however, changes. In the feed zone, the root diameter is small so that the large

channel depth (i.e., distance between the outside and root diameters) can accommodate the

packed solid resin particles. The root diameter of the transition or compression zone in-

creases with the distance from the feed zone. This change in channel depth forces the solid

FIGURE 1.14 General-purpose extruder screw. 57

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.