Page 29 - Handbook of Plastics Technologies

P. 29

INTRODUCTION TO POLYMERS AND PLASTICS

INTRODUCTION TO POLYMERS AND PLASTICS 1.15

TABLE 1.5 Typical Viscosities

Material Viscosity (Pa-s)

Air 10 –5

Water 10 –3

Polymer latexes 10 –2

Olive oil 10 –1

Glycerin 1

2

Polymer melts 10 – 10 6

Pitch 10 9

Plastics 10 12

Glass 10 21

TABLE 1.6 Typical Shear Rates for Selected

Processes 52

Process Shear rate (s-1)

Compression molding 1–10

Calendering 10–100

Extrusion 100–1,000

Injection molding 1,000–10,000

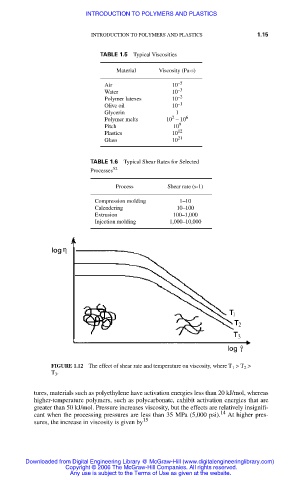

FIGURE 1.12 The effect of shear rate and temperature on viscosity, where T > T >

1

2

T .

3

tures, materials such as polyethylene have activation energies less than 20 kJ/mol, whereas

higher-temperature polymers, such as polycarbonate, exhibit activation energies that are

greater than 50 kJ/mol. Pressure increases viscosity, but the effects are relatively insignifi-

14

cant when the processing pressures are less than 35 MPa (5,000 psi). At higher pres-

15

sures, the increase in viscosity is given by

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.