Page 44 - Handbook of Plastics Technologies

P. 44

INTRODUCTION TO POLYMERS AND PLASTICS

1.30 CHAPTER 1

FIGURE 1.27 Two-shot molding with rotating mold. 67

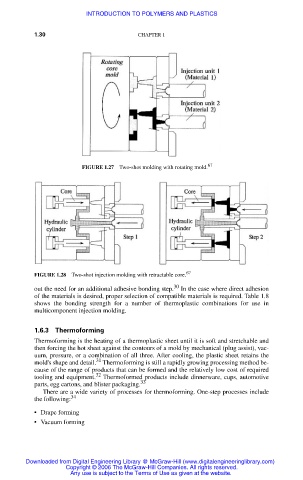

FIGURE 1.28 Two-shot injection molding with retractable core. 67

30

out the need for an additional adhesive bonding step. In the case where direct adhesion

of the materials is desired, proper selection of compatible materials is required. Table 1.8

shows the bonding strength for a number of thermoplastic combinations for use in

multicomponent injection molding.

1.6.3 Thermoforming

Thermoforming is the heating of a thermoplastic sheet until it is soft and stretchable and

then forcing the hot sheet against the contours of a mold by mechanical (plug assist), vac-

uum, pressure, or a combination of all three. After cooling, the plastic sheet retains the

31

mold's shape and detail. Thermoforming is still a rapidly growing processing method be-

cause of the range of products that can be formed and the relatively low cost of required

32

tooling and equipment. Thermoformed products include dinnerware, cups, automotive

33

parts, egg cartons, and blister packaging.

There are a wide variety of processes for thermoforming. One-step processes include

the following: 34

• Drape forming

• Vacuum forming

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.