Page 67 - Handbook of Plastics Technologies

P. 67

THERMOPLASTICS

THERMOPLASTICS 2.7

FIGURE 2.3 Sodium cellulose methylcellulose

structure.

ters, including cellulosehydroxyethyl, hydroxypropylcellulose, and ethylcellulose, are

used in film and coating applications, adhesives, and inks.

2.2.4 Fluoropolymers

Fluoropolymers are noted for their heat-resistance properties. This is due to the strength

48

and stability of the carbon-fluorine bond. The first patent was awarded in 1934 to

IG Farben for a fluorine-containing polymer, polychlorotrifluoroethylene (PCTFE). This

polymer had limited application, and fluoropolymers did not have wide application until

49

the discovery of polytetrafluorethylene (PTFE) in 1938. In addition to their high-temper-

ature properties, fluoropolymers are known for their chemical resistance, very low coeffi-

cient of friction, and good dielectric properties. Their mechanical properties are not high

50

unless reinforcing fillers, such as glass fibers, are added. The compressive properties of

fluoropolymers are generally superior to their tensile properties. In addition to their high

temperature resistance, these materials have very good toughness and flexibility at low

temperatures. 51

A wide variety of fluoropolymers are available, including polytetrafluoroethylene

(PTFE), polychlorotrifluoroethylene (PCTFE), fluorinated ethylene propylene (FEP), eth-

ylene chlorotrifluoroethylene (ECTFE), ethylene tetrafluoroethylene (ETFE), polyvinylin-

dene fluoride (PVDF), and polyvinyl fluoride (PVF).

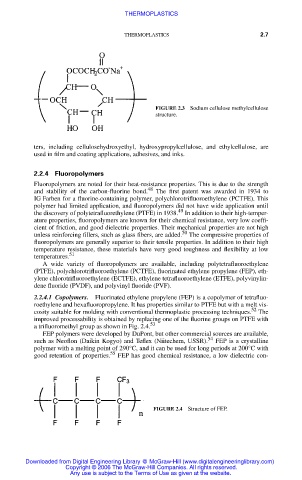

2.2.4.1 Copolymers. Fluorinated ethylene propylene (FEP) is a copolymer of tetrafluo-

roethylene and hexafluoropropylene. It has properties similar to PTFE but with a melt vis-

52

cosity suitable for molding with conventional thermoplastic processing techniques. The

improved processability is obtained by replacing one of the fluorine groups on PTFE with

53

a trifluoromethyl group as shown in Fig. 2.4.

FEP polymers were developed by DuPont, but other commercial sources are available,

54

such as Neoflon (Daikin Kogyo) and Teflex (Niitechem, USSR). FEP is a crystalline

polymer with a melting point of 290°C, and it can be used for long periods at 200°C with

55

good retention of properties. FEP has good chemical resistance, a low dielectric con-

FIGURE 2.4 Structure of FEP.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.