Page 284 - Handbook of Properties of Textile and Technical Fibres

P. 284

258 Handbook of Properties of Textile and Technical Fibres

6.6 21

20.8

Process B

6.55

Process A strength 20.6

Single-fiber strength (gf) 6.45 Process A Process B 20.2 Single-fiber elongation (%)

strength

20.4

6.5

20

19.8

6.4

19.4

6.35 elongation elongation 19.6

Low gin One Low carding

rate lint cleaner rate

High gin Two High carding

rate lint cleaners rate

Process A: low gin rate One lint cleaner Low carding rate

Process B: high gin rate Two lint cleaner High carding rate

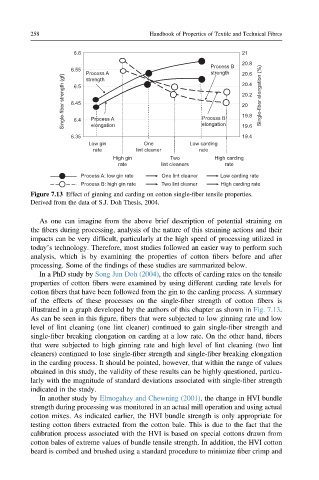

Figure 7.13 Effect of ginning and carding on cotton single-fiber tensile properties.

Derived from the data of S.J. Doh Thesis, 2004.

As one can imagine from the above brief description of potential straining on

the fibers during processing, analysis of the nature of this straining actions and their

impacts can be very difficult, particularly at the high speed of processing utilized in

today’s technology. Therefore, most studies followed an easier way to perform such

analysis, which is by examining the properties of cotton fibers before and after

processing. Some of the findings of these studies are summarized below.

In a PhD study by Song Jun Doh (2004), the effects of carding rates on the tensile

properties of cotton fibers were examined by using different carding rate levels for

cotton fibers that have been followed from the gin to the carding process. A summary

of the effects of these processes on the single-fiber strength of cotton fibers is

illustrated in a graph developed by the authors of this chapter as shown in Fig. 7.13.

As can be seen in this figure, fibers that were subjected to low ginning rate and low

level of lint cleaning (one lint cleaner) continued to gain single-fiber strength and

single-fiber breaking elongation on carding at a low rate. On the other hand, fibers

that were subjected to high ginning rate and high level of lint cleaning (two lint

cleaners) continued to lose single-fiber strength and single-fiber breaking elongation

in the carding process. It should be pointed, however, that within the range of values

obtained in this study, the validity of these results can be highly questioned, particu-

larly with the magnitude of standard deviations associated with single-fiber strength

indicated in the study.

In another study by Elmogahzy and Chewning (2001), the change in HVI bundle

strength during processing was monitored in an actual mill operation and using actual

cotton mixes. As indicated earlier, the HVI bundle strength is only appropriate for

testing cotton fibers extracted from the cotton bale. This is due to the fact that the

calibration process associated with the HVI is based on special cottons drawn from

cotton bales of extreme values of bundle tensile strength. In addition, the HVI cotton

beard is combed and brushed using a standard procedure to minimize fiber crimp and