Page 358 - Handbook of Properties of Textile and Technical Fibres

P. 358

Regenerated cellulosic fibers 331

Cellulose

O Mix with NaOH

NaOH + H 2

Xanthation

CS 2

Dissolving

Filtering

Ripening or

aging

H SO ,

4

2

ZnSO , Spinning CS 2 recovery

4

Na SO 4

2

Washing

bleaching

fiber finishing

drying

Fiber

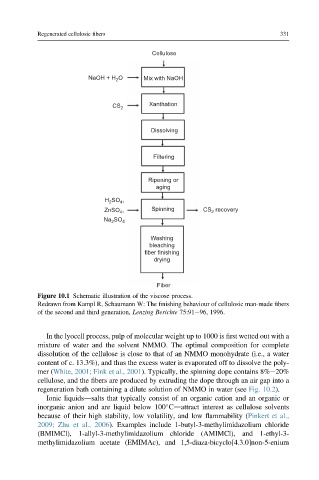

Figure 10.1 Schematic illustration of the viscose process.

Redrawn from Kampl R, Schaumann W: The finishing behaviour of cellulosic man-made fibers

of the second and third generation, Lenzing Berichte 75:91e96, 1996.

In the lyocell process, pulp of molecular weight up to 1000 is first wetted out with a

mixture of water and the solvent NMMO. The optimal composition for complete

dissolution of the cellulose is close to that of an NMMO monohydrate (i.e., a water

content of c. 13.3%), and thus the excess water is evaporated off to dissolve the poly-

mer (White, 2001; Fink et al., 2001). Typically, the spinning dope contains 8%e20%

cellulose, and the fibers are produced by extruding the dope through an air gap into a

regeneration bath containing a dilute solution of NMMO in water (see Fig. 10.2).

Ionic liquidsdsalts that typically consist of an organic cation and an organic or

inorganic anion and are liquid below 100 Cdattract interest as cellulose solvents

because of their high stability, low volatility, and low flammability (Pinkert et al.,

2009; Zhu et al., 2006). Examples include 1-butyl-3-methylimidazolium chloride

(BMIMCl), 1-allyl-3-methylimidazolium chloride (AMIMCl), and 1-ethyl-3-

methylimidazolium acetate (EMIMAc), and 1,5-diaza-bicyclo[4.3.0]non-5-enium