Page 463 - Handbook of Properties of Textile and Technical Fibres

P. 463

436 Handbook of Properties of Textile and Technical Fibres

connected to the number-averaged molecular weight M n of PET by the Mark Houwink

equation:

½h¼ KM a (13.3)

n

5

where a ¼ 0.898 and K ¼ 5.41$10 dL/g, were found by regression for high

molecular weight of PET and solvent dichloromethane/trifluoroacetic acid (Huang

et al., 1994). The molecular weight corresponding to intrinsic viscosity (h) ¼ 0.8 dL/g

is M ¼ 44,000 and for viscosity (h) ¼ 0.9 dL/g is M ¼ 50,200.

The delivery pump must provide a pressure of about 100e200 bars to force the flow

through the pack, which contains filtration media (e.g., sand) to remove any particles

larger than a few mm.

Standard spinning nozzles have holes of 0.1e1 mm in diameter. The polymer

throughput per hole is usually in the range of le5 g/hole min. The extrusion velocity,

i.e., exit velocity from the spinneret v B (m/min) depends on the amount of melt mass

passing through the hole, hole diameter, and density of the melt. Typical values of v B

are about 10e30 m/min (Fourné, 1999).

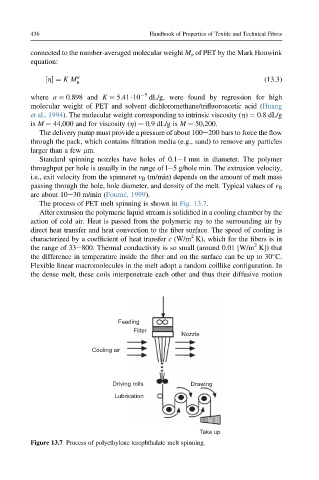

The process of PET melt spinning is shown in Fig. 13.7.

After extrusion the polymeric liquid stream is solidified in a cooling chamber by the

action of cold air. Heat is passed from the polymeric ray to the surrounding air by

direct heat transfer and heat convection to the fiber surface. The speed of cooling is

2

characterized by a coefficient of heat transfer c (W/m K), which for the fibers is in

2

the range of 33e800. Thermal conductivity is so small (around 0.01 [W/m K]) that

the difference in temperature inside the fiber and on the surface can be up to 30 C.

Flexible linear macromolecules in the melt adopt a random coillike configuration. In

the dense melt, these coils interpenetrate each other and thus their diffusive motion

Feeding

Filter

Nozzle

Cooling air

Driving rolls Drawing

Lubrication

Take up

Figure 13.7 Process of polyethylene terephthalate melt spinning.