Page 186 - Handbook of Structural Steel Connection Design and Details

P. 186

Source: Handbook of Structural Steel Connection Design and Details

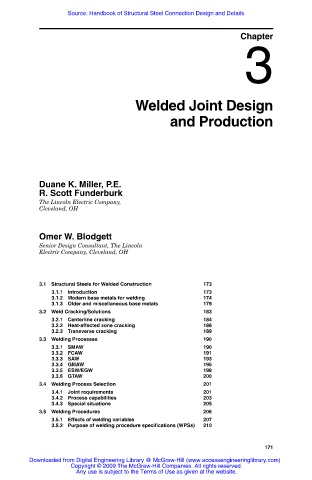

Chapter

3

Welded Joint Design

and Production

Duane K. Miller, P.E.

R. Scott Funderburk

The Lincoln Electric Company,

Cleveland, OH

Omer W. Blodgett

Senior Design Consultant, The Lincoln

Electric Company, Cleveland, OH

3.1 Structural Steels for Welded Construction 173

3.1.1 Introduction 173

3.1.2 Modern base metals for welding 174

3.1.3 Older and miscellaneous base metals 179

3.2 Weld Cracking/Solutions 183

3.2.1 Centerline cracking 184

3.2.2 Heat-affected zone cracking 186

3.2.3 Transverse cracking 189

3.3 Welding Processes 190

3.3.1 SMAW 190

3.3.2 FCAW 191

3.3.3 SAW 193

3.3.4 GMAW 195

3.3.5 ESW/EGW 198

3.3.6 GTAW 200

3.4 Welding Process Selection 201

3.4.1 Joint requirements 201

3.4.2 Process capabilities 203

3.4.3 Special situations 205

3.5 Welding Procedures 206

3.5.1 Effects of welding variables 207

3.5.2 Purpose of welding procedure specifications (WPSs) 210

171

Downloaded from Digital Engineering Library @ McGraw-Hill (www.accessengineeringlibrary.com)

Copyright © 2009 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.