Page 217 - Handbook of Structural Steel Connection Design and Details

P. 217

Welded Joint Design and Production

202 Chapter Three

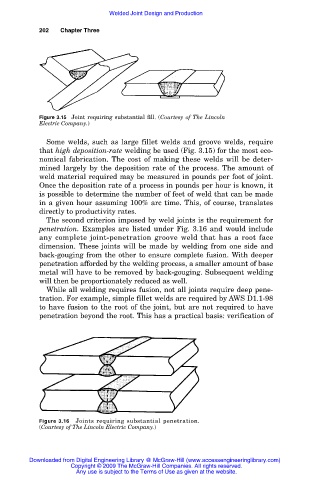

Figure 3.15 Joint requiring substantial fill. (Courtesy of The Lincoln

Electric Company.)

Some welds, such as large fillet welds and groove welds, require

that high deposition-rate welding be used (Fig. 3.15) for the most eco-

nomical fabrication. The cost of making these welds will be deter-

mined largely by the deposition rate of the process. The amount of

weld material required may be measured in pounds per foot of joint.

Once the deposition rate of a process in pounds per hour is known, it

is possible to determine the number of feet of weld that can be made

in a given hour assuming 100% arc time. This, of course, translates

directly to productivity rates.

The second criterion imposed by weld joints is the requirement for

penetration. Examples are listed under Fig. 3.16 and would include

any complete joint-penetration groove weld that has a root face

dimension. These joints will be made by welding from one side and

back-gouging from the other to ensure complete fusion. With deeper

penetration afforded by the welding process, a smaller amount of base

metal will have to be removed by back-gouging. Subsequent welding

will then be proportionately reduced as well.

While all welding requires fusion, not all joints require deep pene-

tration. For example, simple fillet welds are required by AWS D1.1-98

to have fusion to the root of the joint, but are not required to have

penetration beyond the root. This has a practical basis: verification of

Figure 3.16 Joints requiring substantial penetration.

(Courtesy of The Lincoln Electric Company.)

Downloaded from Digital Engineering Library @ McGraw-Hill (www.accessengineeringlibrary.com)

Copyright © 2009 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.