Page 215 - Handbook of Structural Steel Connection Design and Details

P. 215

Welded Joint Design and Production

200 Chapter Three

against the water-cooled copper shoes. In some cases, steel dams

instead of copper dams are used to retain the puddle. After completion

of the weld, the steel dams stay in place, and become part of the final

product. Slag must be replenished, and additional flux is continuously

added to compensate for the loss.

One aspect of electroslag welding that must be considered is the

very high heat input associated with the process. This causes a large

heat-affected zone (HAZ) that may have a lower notch toughness.

Electroslag welding is different from electroslag, inasmuch as no flux

is used. Electrogas welding is a true arc-welding process and is con-

ceptually more like gas metal arc or flux-cored arc welding. A solid or

tubular electrode is fed into the joint, which is flooded with an inert

gas shield. The arc progresses vertically while the puddle is retained

by the water-cooled dams.

The HAZ performance is dependent not only on the heat input, but

also on the nature of the steel. While all processes develop a heat-

affected zone, the large size of the electroslag heat-affected zone jus-

tifies additional scrutiny. Advances in steel technology have resulted

in improved steels, featuring higher cleanliness and toughness, that

better retain the HAZ properties in ESW/EGW welds.

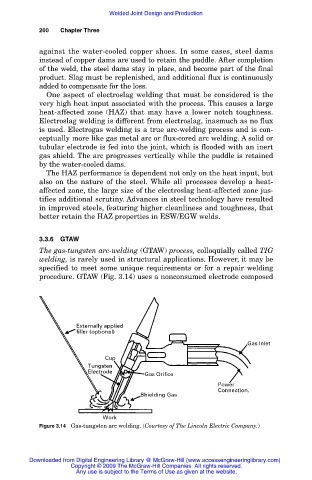

3.3.6 GTAW

The gas-tungsten arc-welding (GTAW) process, colloquially called TIG

welding, is rarely used in structural applications. However, it may be

specified to meet some unique requirements or for a repair welding

procedure. GTAW (Fig. 3.14) uses a nonconsumed electrode composed

Figure 3.14 Gas-tungsten arc welding. (Courtesy of The Lincoln Electric Company.)

Downloaded from Digital Engineering Library @ McGraw-Hill (www.accessengineeringlibrary.com)

Copyright © 2009 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.