Page 210 - Handbook of Structural Steel Connection Design and Details

P. 210

Welded Joint Design and Production

Welded Joint Design and Production 195

drives, and feeds two electrodes independently. Some applications,

such as the manufacture of line pipe, may use up to five independent

electrodes in a multiple-electrode configuration. AC welding is typi-

cally used for multielectrode welding. If dc current is used, it is limited

usually to the lead electrode to minimize the potentially negative

interaction of magnetic fields between the two electrodes.

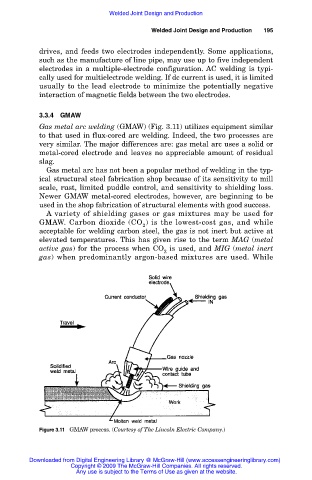

3.3.4 GMAW

Gas metal arc welding (GMAW) (Fig. 3.11) utilizes equipment similar

to that used in flux-cored arc welding. Indeed, the two processes are

very similar. The major differences are: gas metal arc uses a solid or

metal-cored electrode and leaves no appreciable amount of residual

slag.

Gas metal arc has not been a popular method of welding in the typ-

ical structural steel fabrication shop because of its sensitivity to mill

scale, rust, limited puddle control, and sensitivity to shielding loss.

Newer GMAW metal-cored electrodes, however, are beginning to be

used in the shop fabrication of structural elements with good success.

A variety of shielding gases or gas mixtures may be used for

GMAW. Carbon dioxide (CO ) is the lowest-cost gas, and while

2

acceptable for welding carbon steel, the gas is not inert but active at

elevated temperatures. This has given rise to the term MAG (metal

active gas) for the process when CO is used, and MIG (metal inert

2

gas) when predominantly argon-based mixtures are used. While

Figure 3.11 GMAW process. (Courtesy of The Lincoln Electric Company.)

Downloaded from Digital Engineering Library @ McGraw-Hill (www.accessengineeringlibrary.com)

Copyright © 2009 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.