Page 205 - Handbook of Structural Steel Connection Design and Details

P. 205

Welded Joint Design and Production

190 Chapter Three

Preheat may have to be applied to alleviate transverse cracking.

The preheat will assist in diffusing hydrogen. As preheat is applied, it

will additionally expand the length of the weld joint, allowing the

weld metal and the joint to contract simultaneously, and reducing the

applied stress to the shrinking weld. This is particularly important

when making circumferential welds. When the circumference of the

materials being welded is expanded, the weld metal is free to contract

along with the surrounding base material, reducing the longitudinal

shrinkage stress. Finally, postweld hydrogen-release treatments that

involve holding the steel at 250 to 450°F for extended times will

assist in diffusing any residual hydrogen.

3.3 Welding Processes

A variety of welding processes can be used for fabrication in struc-

tural applications. However, it is important that all parties involved

understand these processes in order to ensure quality and economi-

cal fabrication. A brief description of the major processes is provided

below.

3.3.1 SMAW

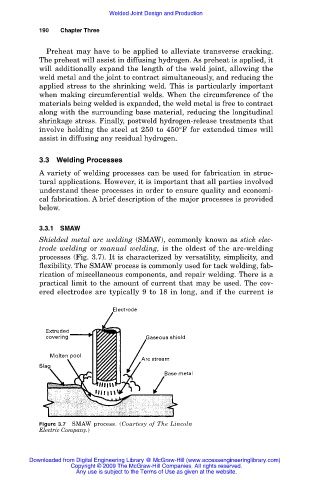

Shielded metal arc welding (SMAW), commonly known as stick elec-

trode welding or manual welding, is the oldest of the arc-welding

processes (Fig. 3.7). It is characterized by versatility, simplicity, and

flexibility. The SMAW process is commonly used for tack welding, fab-

rication of miscellaneous components, and repair welding. There is a

practical limit to the amount of current that may be used. The cov-

ered electrodes are typically 9 to 18 in long, and if the current is

Figure 3.7 SMAW process. (Courtesy of The Lincoln

Electric Company.)

Downloaded from Digital Engineering Library @ McGraw-Hill (www.accessengineeringlibrary.com)

Copyright © 2009 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.