Page 200 - Handbook of Structural Steel Connection Design and Details

P. 200

Welded Joint Design and Production

Welded Joint Design and Production 185

Figure 3.2 Buttering. (Courtesy of The Lincoln Electric

Company.)

In the case of sulfur, it is possible to overcome the harmful effects of

iron sulfides by preferentially forming manganese sulfide. Manganese

sulfide (MnS) is created when manganese is present in sufficient

quantities to counteract the sulfur. Manganese sulfide has a melting

point of 2900°F. In this situation, before the weld metal begins to

solidify, manganese sulfides are formed which do not segregate. Steel

producers utilize this concept when higher levels of sulfur are encoun-

tered in the iron ore. In welding, it is possible to use filler materials

with higher levels of manganese to overcome the formation of low

melting-point iron sulfide. Unfortunately, this concept cannot be

applied to contaminants other than sulfur.

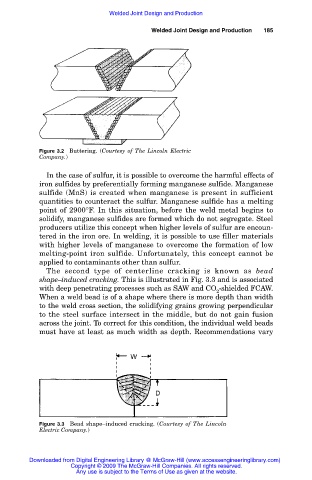

The second type of centerline cracking is known as bead

shape–induced cracking. This is illustrated in Fig. 3.3 and is associated

with deep penetrating processes such as SAW and CO -shielded FCAW.

2

When a weld bead is of a shape where there is more depth than width

to the weld cross section, the solidifying grains growing perpendicular

to the steel surface intersect in the middle, but do not gain fusion

across the joint. To correct for this condition, the individual weld beads

must have at least as much width as depth. Recommendations vary

Figure 3.3 Bead shape–induced cracking. (Courtesy of The Lincoln

Electric Company.)

Downloaded from Digital Engineering Library @ McGraw-Hill (www.accessengineeringlibrary.com)

Copyright © 2009 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.