Page 201 - Handbook of Structural Steel Connection Design and Details

P. 201

Welded Joint Design and Production

186 Chapter Three

from a 1:1 to a 1.4:1 width-to-depth ratio to remedy this condition. The

total weld configuration, which may have many individual weld beads,

can have an overall profile that constitutes more depth than width. If

multiple passes are used in this situation, and each bead is wider than

it is deep, a crack-free weld can be made.

When centerline cracking due to bead shape is experienced, the

obvious solution is to change the width-to-depth relationship. This

may involve a change in joint design. Since the depth is a function of

penetration, it is advisable to reduce the amount of penetration. This

can be accomplished by utilizing lower welding amperages and larger-

diameter electrodes. All of these approaches will reduce the current

density and limit the amount of penetration.

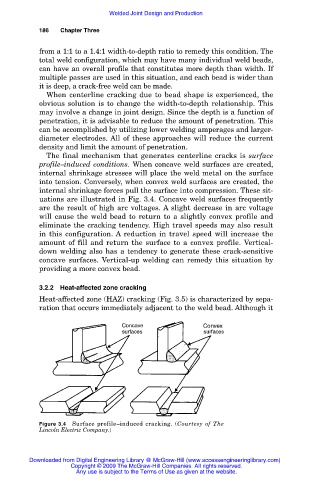

The final mechanism that generates centerline cracks is surface

profile–induced conditions. When concave weld surfaces are created,

internal shrinkage stresses will place the weld metal on the surface

into tension. Conversely, when convex weld surfaces are created, the

internal shrinkage forces pull the surface into compression. These sit-

uations are illustrated in Fig. 3.4. Concave weld surfaces frequently

are the result of high arc voltages. A slight decrease in arc voltage

will cause the weld bead to return to a slightly convex profile and

eliminate the cracking tendency. High travel speeds may also result

in this configuration. A reduction in travel speed will increase the

amount of fill and return the surface to a convex profile. Vertical-

down welding also has a tendency to generate these crack-sensitive

concave surfaces. Vertical-up welding can remedy this situation by

providing a more convex bead.

3.2.2 Heat-affected zone cracking

Heat-affected zone (HAZ) cracking (Fig. 3.5) is characterized by sepa-

ration that occurs immediately adjacent to the weld bead. Although it

Figure 3.4 Surface profile–induced cracking. (Courtesy of The

Lincoln Electric Company.)

Downloaded from Digital Engineering Library @ McGraw-Hill (www.accessengineeringlibrary.com)

Copyright © 2009 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.