Page 199 - Handbook of Structural Steel Connection Design and Details

P. 199

Welded Joint Design and Production

184 Chapter Three

3.2.1 Centerline cracking

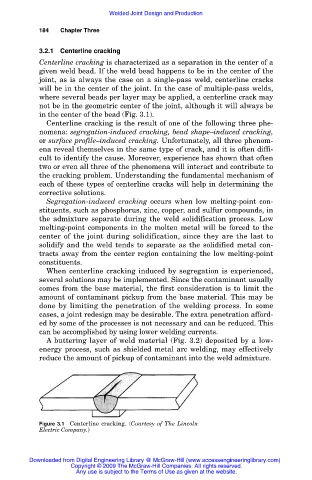

Centerline cracking is characterized as a separation in the center of a

given weld bead. If the weld bead happens to be in the center of the

joint, as is always the case on a single-pass weld, centerline cracks

will be in the center of the joint. In the case of multiple-pass welds,

where several beads per layer may be applied, a centerline crack may

not be in the geometric center of the joint, although it will always be

in the center of the bead (Fig. 3.1).

Centerline cracking is the result of one of the following three phe-

nomena: segregation-induced cracking, bead shape–induced cracking,

or surface profile–induced cracking. Unfortunately, all three phenom-

ena reveal themselves in the same type of crack, and it is often diffi-

cult to identify the cause. Moreover, experience has shown that often

two or even all three of the phenomena will interact and contribute to

the cracking problem. Understanding the fundamental mechanism of

each of these types of centerline cracks will help in determining the

corrective solutions.

Segregation-induced cracking occurs when low melting-point con-

stituents, such as phosphorus, zinc, copper, and sulfur compounds, in

the admixture separate during the weld solidification process. Low

melting-point components in the molten metal will be forced to the

center of the joint during solidification, since they are the last to

solidify and the weld tends to separate as the solidified metal con-

tracts away from the center region containing the low melting-point

constituents.

When centerline cracking induced by segregation is experienced,

several solutions may be implemented. Since the contaminant usually

comes from the base material, the first consideration is to limit the

amount of contaminant pickup from the base material. This may be

done by limiting the penetration of the welding process. In some

cases, a joint redesign may be desirable. The extra penetration afford-

ed by some of the processes is not necessary and can be reduced. This

can be accomplished by using lower welding currents.

A buttering layer of weld material (Fig. 3.2) deposited by a low-

energy process, such as shielded metal arc welding, may effectively

reduce the amount of pickup of contaminant into the weld admixture.

Figure 3.1 Centerline cracking. (Courtesy of The Lincoln

Electric Company.)

Downloaded from Digital Engineering Library @ McGraw-Hill (www.accessengineeringlibrary.com)

Copyright © 2009 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.