Page 208 - Handbook of Structural Steel Connection Design and Details

P. 208

Welded Joint Design and Production

Welded Joint Design and Production 193

flux-cored electrodes are better for field-welding situations. Since no

externally supplied shielding gas is required, the process may be used in

high winds without adversely affecting the quality of the deposit. With

any of the gas-shielded processes, wind shields must be erected to pre-

clude interference with the gas shield in windy weather. Many fabrica-

tors have found self-shielded flux core offers advantages for shop

welding as well, since it permits the use of better ventilation.

Individual gas-shielded flux-cored electrodes tend to be more versa-

tile than self-shielded flux-cored electrodes, and in general, provide

better arc action. Operator appeal is usually higher. While the gas

shield must be protected from winds and drafts, this is not particularly

difficult in shop fabrication situations. Weld appearance and quality

are very good. Higher-strength gas-shielded FCAW electrodes are

available, while current technology limits self-shielded FCAW

deposits to 90-ksi tensile strength or less.

3.3.3 SAW

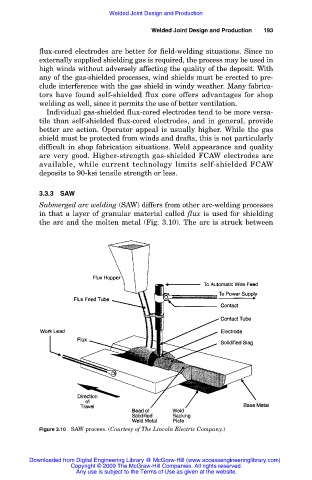

Submerged arc welding (SAW) differs from other arc-welding processes

in that a layer of granular material called flux is used for shielding

the arc and the molten metal (Fig. 3.10). The arc is struck between

Figure 3.10 SAW process. (Courtesy of The Lincoln Electric Company.)

Downloaded from Digital Engineering Library @ McGraw-Hill (www.accessengineeringlibrary.com)

Copyright © 2009 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.