Page 235 - Handbook of Structural Steel Connection Design and Details

P. 235

Welded Joint Design and Production

220 Chapter Three

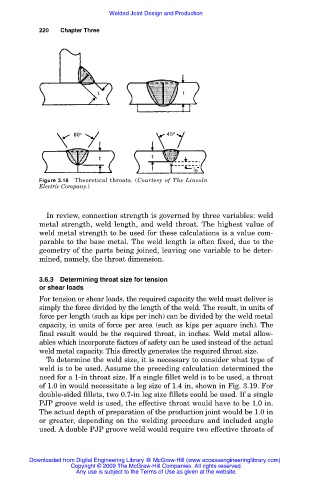

Figure 3.18 Theoretical throats. (Courtesy of The Lincoln

Electric Company.)

In review, connection strength is governed by three variables: weld

metal strength, weld length, and weld throat. The highest value of

weld metal strength to be used for these calculations is a value com-

parable to the base metal. The weld length is often fixed, due to the

geometry of the parts being joined, leaving one variable to be deter-

mined, namely, the throat dimension.

3.6.3 Determining throat size for tension

or shear loads

For tension or shear loads, the required capacity the weld must deliver is

simply the force divided by the length of the weld. The result, in units of

force per length (such as kips per inch) can be divided by the weld metal

capacity, in units of force per area (such as kips per square inch). The

final result would be the required throat, in inches. Weld metal allow-

ables which incorporate factors of safety can be used instead of the actual

weld metal capacity. This directly generates the required throat size.

To determine the weld size, it is necessary to consider what type of

weld is to be used. Assume the preceding calculation determined the

need for a 1-in throat size. If a single fillet weld is to be used, a throat

of 1.0 in would necessitate a leg size of 1.4 in, shown in Fig. 3.19. For

double-sided fillets, two 0.7-in leg size fillets could be used. If a single

PJP groove weld is used, the effective throat would have to be 1.0 in.

The actual depth of preparation of the production joint would be 1.0 in

or greater, depending on the welding procedure and included angle

used. A double PJP groove weld would require two effective throats of

Downloaded from Digital Engineering Library @ McGraw-Hill (www.accessengineeringlibrary.com)

Copyright © 2009 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.