Page 278 - Handbook of Structural Steel Connection Design and Details

P. 278

Welded Joint Design and Production

Welded Joint Design and Production 263

importantly, WPSs are not simply pieces of documentation to be filed

away—they are intended to be communication tools for maintenance

of weld quality. It is essential that all parties involved with the fabri-

cation sequence have access to these documents to ensure confor-

mance to their requirements.

Effect of welding variables. A variety of welding variables determine

the quality of the deposited weld metal. These variables are a function

of the particular welding process being used, but the general trends

outlined below are applicable to all welding processes.

Amperage is a measure of the amount of current flowing through

the electrode and the work. It is a primary variable in determining

heat input. An increase in amperage generally means higher deposi-

tion rates, deeper penetration, and more melting of base metal. The

role of amperage is best understood in the context of heat input and

current density, which are described below.

Arc voltage is directly related to arc length. As the voltage increases,

the arc length increases. Excessively high voltages may lead to weld

metal porosity, while extremely low voltages will result in poor weld

bead shapes. In an electric circuit, the voltage is not constant but is

composed of a series of voltage drops. For this reason, it is important

to monitor voltage near the arc.

Travel speed is the rate at which the electrode is moved relative to

the joint. All other variables being equal, travel speed has an inverse

effect on the size of weld beads. Travel speed is a key variable used in

determining heat input.

Polarity is a definition of the direction of current flow. Positive

polarity (or reverse) is achieved when the electrode lead is connected

lo the positive terminal of the dc power supply. The work lead would

be connected to the negative terminal. Negative polarity (or straight)

occurs when the electrode is connected to the negative terminal. For

most welding processes, the required electrode polarity is a function

of the design of the electrode. For submerged arc welding, either

polarity could be utilized.

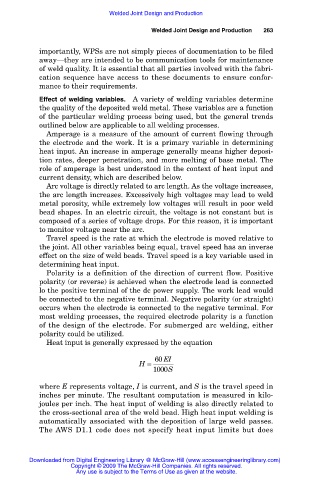

Heat input is generally expressed by the equation

60 EI

H =

1000 S

where E represents voltage, I is current, and S is the travel speed in

inches per minute. The resultant computation is measured in kilo-

joules per inch. The heat input of welding is also directly related to

the cross-sectional area of the weld bead. High heat input welding is

automatically associated with the deposition of large weld passes.

The AWS D1.1 code does not specify heat input limits but does

Downloaded from Digital Engineering Library @ McGraw-Hill (www.accessengineeringlibrary.com)

Copyright © 2009 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.