Page 119 - Handbook of Surface Improvement and Modification

P. 119

114 Surface Tension and Wetting

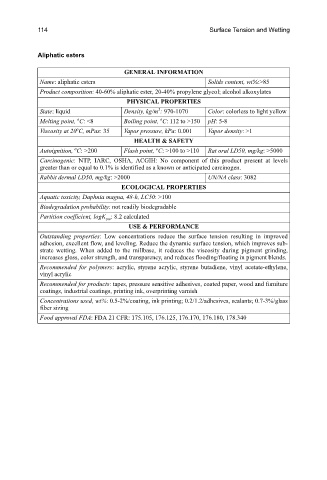

Aliphatic esters

GENERAL INFORMATION

Name: aliphatic esters Solids content, wt%:>85

Product composition: 40-60% aliphatic ester, 20-40% propylene glycol; alcohol alkoxylates

PHYSICAL PROPERTIES

3

State: liquid Density, kg/m : 970-1070 Color: colorless to light yellow

o

o

Melting point, C: <8 Boiling point, C: 112 to >150 pH: 5-8

o

Viscosity at 20 C, mPas: 35 Vapor pressure, kPa: 0.001 Vapor density: >1

HEALTH & SAFETY

o

o

Autoignition, C: >200 Flash point, C: >100 to >110 Rat oral LD50, mg/kg: >5000

Carcinogenic: NTP, IARC, OSHA, ACGIH: No component of this product present at levels

greater than or equal to 0.1% is identified as a known or anticipated carcinogen.

Rabbit dermal LD50, mg/kg: >2000 UN/NA class: 3082

ECOLOGICAL PROPERTIES

Aquatic toxicity, Daphnia magna, 48-h, LC50: >100

Biodegradation probability: not readily biodegradable

Partition coefficient, logK : 8.2 calculated

ow

USE & PERFORMANCE

Outstanding properties: Low concentrations reduce the surface tension resulting in improved

adhesion, excellent flow, and leveling. Reduce the dynamic surface tension, which improves sub-

strate wetting. When added to the millbase, it reduces the viscosity during pigment grinding,

increases gloss, color strength, and transparency, and reduces flooding/floating in pigment blends.

Recommended for polymers: acrylic, styrene acrylic, styrene butadiene, vinyl acetate-ethylene,

vinyl acrylic

Recommended for products: tapes, pressure sensitive adhesives, coated paper, wood and furniture

coatings, industrial coatings, printing ink, overprinting varnish

Concentrations used, wt%: 0.5-2%/coating, ink printing; 0.2/1.2/adhesives, sealants; 0.7-3%/glass

fiber sizing

Food approval FDA: FDA 21 CFR: 175.105, 176.125, 176.170, 176.180, 178.340