Page 118 - Handbook of Surface Improvement and Modification

P. 118

7.2 Additives used 113

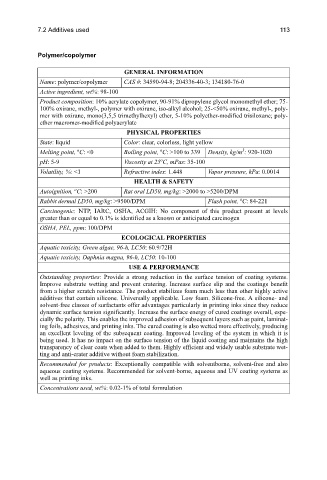

Polymer/copolymer

GENERAL INFORMATION

Name: polymer/copolymer CAS #: 34590-94-8; 204336-40-3; 134180-76-0

Active ingredient, wt%: 98-100

Product composition: 10% acrylate copolymer, 90-91% dipropylene glycol monomethyl ether; 75-

100% oxirane, methyl-, polymer with oxirane, iso-alkyl alcohol; 25-<50% oxirane, methyl-, poly-

mer with oxirane, mono(3,5,5 trimethylhexyl) ether, 5-10% polyether-modified trisiloxane; poly-

ether macromer-modified polyacrylate

PHYSICAL PROPERTIES

State: liquid Color: clear, colorless, light yellow

3

o

o

Melting point, C: <0 Boiling point, C: >100 to 339 Density, kg/m : 920-1020

o

pH: 5-9 Viscosity at 25 C, mPas: 35-100

Volatility, %: <1 Refractive index: 1.448 Vapor pressure, kPa: 0.0014

HEALTH & SAFETY

o

Autoignition, C: >200 Rat oral LD50, mg/kg: >2000 to >5200/DPM

o

Rabbit dermal LD50, mg/kg: >9500/DPM Flash point, C: 84-221

Carcinogenic: NTP, IARC, OSHA, ACGIH: No component of this product present at levels

greater than or equal to 0.1% is identified as a known or anticipated carcinogen

OSHA, PEL, ppm: 100/DPM

ECOLOGICAL PROPERTIES

Aquatic toxicity, Green algae, 96-h, LC50: 60.9/72H

Aquatic toxicity, Daphnia magna, 96-h, LC50: 10-100

USE & PERFORMANCE

Outstanding properties: Provide a strong reduction in the surface tension of coating systems.

Improve substrate wetting and prevent cratering. Increase surface slip and the coatings benefit

from a higher scratch resistance. The product stabilizes foam much less than other highly active

additives that contain silicone. Universally applicable. Low foam. Silicone-free. A silicone- and

solvent-free classes of surfactants offer advantages particularly in printing inks since they reduce

dynamic surface tension significantly. Increase the surface energy of cured coatings overall, espe-

cially the polarity. This enables the improved adhesion of subsequent layers such as paint, laminat-

ing foils, adhesives, and printing inks. The cured coating is also wetted more effectively, producing

an excellent leveling of the subsequent coating. Improved leveling of the system in which it is

being used. It has no impact on the surface tension of the liquid coating and maintains the high

transparency of clear coats when added to them. Highly efficient and widely usable substrate wet-

ting and anti-crater additive without foam stabilization.

Recommended for products: Exceptionally compatible with solventborne, solvent-free and also

aqueous coating systems. Recommended for solvent-borne, aqueous and UV coating systems as

well as printing inks.

Concentrations used, wt%: 0.02-1% of total formulation