Page 195 - Handbook of Surface Improvement and Modification

P. 195

190 The Coefficient of Friction

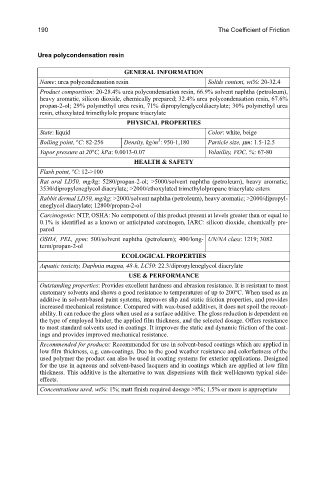

Urea polycondensation resin

GENERAL INFORMATION

Name: urea polycondensation resin Solids content, wt%: 20-32.4

Product composition: 20-28.4% urea polycondensation resin, 66.9% solvent naphtha (petroleum),

heavy aromatic, silicon dioxide, chemically prepared; 32.4% urea polycondensation resin, 67.6%

propan-2-ol; 29% polymethyl urea resin, 71% dipropylenglycoldiacrylate; 30% polymethyl urea

resin, ethoxylated trimethylole propane triacrylate

PHYSICAL PROPERTIES

State: liquid Color: white, beige

3

o

Boiling point, C: 82-256 Density, kg/m : 950-1,180 Particle size, μm: 1.5-12.5

o

Vapor pressure at 20 C, kPa: 0.0013-0.07 Volatility, VOC, %: 67-80

HEALTH & SAFETY

o

Flash point, C: 12->100

Rat oral LD50, mg/kg: 5280/propan-2-ol; >5000/solvent naphtha (petroleum), heavy aromatic;

3530/dipropyleneglycol diacrylate; >2000/ethoxylated trimethylolpropane triacrylate esters

Rabbit dermal LD50, mg/kg: >2000/solvent naphtha (petroleum), heavy aromatic; >2000/dipropyl-

eneglycol diacrylate; 12800/propan-2-ol

Carcinogenic: NTP, OSHA: No component of this product present at levels greater than or equal to

0.1% is identified as a known or anticipated carcinogen, IARC: silicon dioxide, chemically pre-

pared

OSHA, PEL, ppm: 500/solvent naphtha (petroleum); 400/long- UN/NA class: 1219; 3082

term/propan-2-ol

ECOLOGICAL PROPERTIES

Aquatic toxicity, Daphnia magna, 48-h, LC50: 22.3/dipropyleneglycol diacrylate

USE & PERFORMANCE

Outstanding properties: Provides excellent hardness and abrasion resistance. It is resistant to most

o

customary solvents and shows a good resistance to temperatures of up to 200 C. When used as an

additive in solvent-based paint systems, improves slip and static friction properties, and provides

increased mechanical resistance. Compared with wax-based additives, it does not spoil the recoat-

ability. It can reduce the gloss when used as a surface additive. The gloss reduction is dependent on

the type of employed binder, the applied film thickness, and the selected dosage. Offers resistance

to most standard solvents used in coatings. It improves the static and dynamic friction of the coat-

ings and provides improved mechanical resistance.

Recommended for products: Recommended for use in solvent-based coatings which are applied in

low film thickness, e.g. can-coatings. Due to the good weather resistance and colorfastness of the

used polymer the product can also be used in coating systems for exterior applications. Designed

for the use in aqueous and solvent-based lacquers and in coatings which are applied at low film

thickness. This additive is the alternative to wax dispersions with their well-known typical side-

effects.

Concentrations used, wt%: 1%; matt finish required dosage >8%; 1.5% or more is appropriate