Page 222 - How To Implement Lean Manufacturing

P. 222

200 Cha pte r T h i r tee n

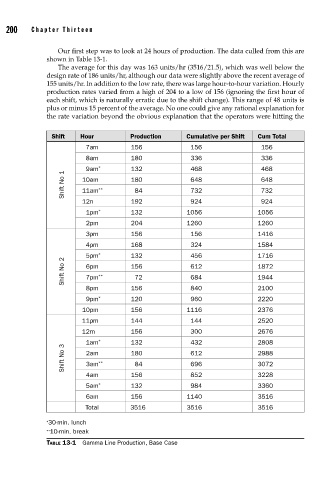

Our first step was to look at 24 hours of production. The data culled from this are

shown in Table 13-1.

The average for this day was 163 units/hr (3516/21.5), which was well below the

design rate of 186 units/hr, although our data were slightly above the recent average of

155 units/hr. In addition to the low rate, there was large hour-to-hour variation. Hourly

production rates varied from a high of 204 to a low of 156 (ignoring the first hour of

each shift, which is naturally erratic due to the shift change). This range of 48 units is

plus or minus 15 percent of the average. No one could give any rational explanation for

the rate variation beyond the obvious explanation that the operators were hitting the

Shift Hour Production Cumulative per Shift Cum Total

7am 156 156 156

8am 180 336 336

9am * 132 468 468

Shift No 1 10am ** 180 648 648

84

732

11am

732

12n 192 924 924

1pm * 132 1056 1056

2pm 204 1260 1260

3pm 156 156 1416

4pm 168 324 1584

5pm * 132 456 1716

Shift No 2 6pm ** 156 612 1872

684

1944

7pm

72

8pm 156 840 2100

9pm * 120 960 2220

10pm 156 1116 2376

11pm 144 144 2520

12m 156 300 2676

1am * 132 432 2808

Shift No 3 2am ** 180 612 2988

696

3072

3am

84

4am 156 852 3228

5am * 132 984 3360

6am 156 1140 3516

Total 3516 3516 3516

∗ 30-min. lunch

∗∗ 10-min. break

TABLE 13-1 Gamma Line Production, Base Case