Page 92 - Hybrid Enhanced Oil Recovery Using Smart Waterflooding

P. 92

84 Hybrid Enhanced Oil Recovery using Smart Waterflooding

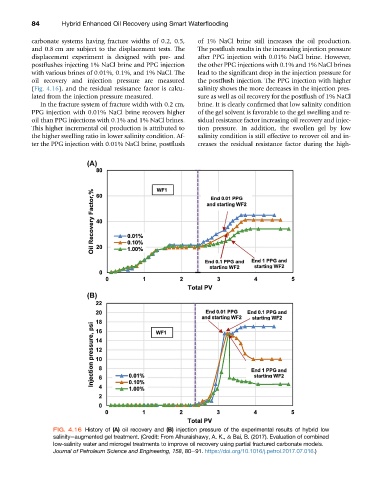

carbonate systems having fracture widths of 0.2, 0.5, of 1% NaCl brine still increases the oil production.

and 0.8 cm are subject to the displacement tests. The The postflush results in the increasing injection pressure

displacement experiment is designed with pre- and after PPG injection with 0.01% NaCl brine. However,

postflushes injecting 1% NaCl brine and PPG injection the other PPG injections with 0.1% and 1% NaCl brines

with various brines of 0.01%, 0.1%, and 1% NaCl. The lead to the significant drop in the injection pressure for

oil recovery and injection pressure are measured the postflush injection. The PPG injection with higher

(Fig. 4.16), and the residual resistance factor is calcu- salinity shows the more decreases in the injection pres-

lated from the injection pressure measured. sure as well as oil recovery for the postflush of 1% NaCl

In the fracture system of fracture width with 0.2 cm, brine. It is clearly confirmed that low salinity condition

PPG injection with 0.01% NaCl brine recovers higher of the gel solvent is favorable to the gel swelling and re-

oil than PPG injections with 0.1% and 1% NaCl brines. sidual resistance factor increasing oil recovery and injec-

This higher incremental oil production is attributed to tion pressure. In addition, the swollen gel by low

the higher swelling ratio in lower salinity condition. Af- salinity condition is still effective to recover oil and in-

ter the PPG injection with 0.01% NaCl brine, postflush creases the residual resistance factor during the high-

FIG. 4.16 History of (A) oil recovery and (B) injection pressure of the experimental results of hybrid low

salinityeaugmented gel treatment. (Credit: From Alhuraishawy, A. K., & Bai, B. (2017). Evaluation of combined

low-salinity water and microgel treatments to improve oil recovery using partial fractured carbonate models.

Journal of Petroleum Science and Engineering, 158,80e91. https://doi.org/10.1016/j.petrol.2017.07.016.)