Page 281 - Hydrocarbon

P. 281

268 Oil and Gas Processing

Table 11.1 Typical product specifications

Oil True vapour pressure (TVP) o83 kPa @ 151

Base sediment and water (BS&W) o0.5 vol%

Temperature WPour point

Salinity (NaCl) o70 g/m 3

3

Hydrogen sulphide (H 2 S) o70 g/m

Gas Liquid content o100 mg/m 3

Water dew point at 51C o7Pa

Heating value W25 MJ/m 3

Composition, CO 2 ,N 2 ,H 2 S

Delivery pressure and temperature

Water Dispersed oil content o40 ppm

Suspended solids content o50 g/m 3

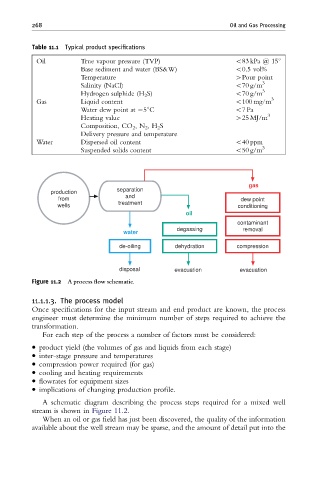

gas

separation

production

and

from dew point

wells treatment conditioning

oil

contaminant

degassing removal

water

de-oiling dehydration compression

disposal evacuation evacuation

Figure 11.2 A process £ow schematic.

11.1.1.3. The process model

Once specifications for the input stream and end product are known, the process

engineer must determine the minimum number of steps required to achieve the

transformation.

For each step of the process a number of factors must be considered:

product yield (the volumes of gas and liquids from each stage)

inter-stage pressure and temperatures

compression power required (for gas)

cooling and heating requirements

flowrates for equipment sizes

implications of changing production profile.

A schematic diagram describing the process steps required for a mixed well

stream is shown in Figure 11.2.

When an oil or gas field has just been discovered, the quality of the information

available about the well stream may be sparse, and the amount of detail put into the