Page 100 - Hydrocarbon Exploration and Production Second Edition

P. 100

Safety and the Environment 87

Identify and describe

potential hazards

Evaluate likelihood and

consequences of hazard

Apply risk reduction

measures

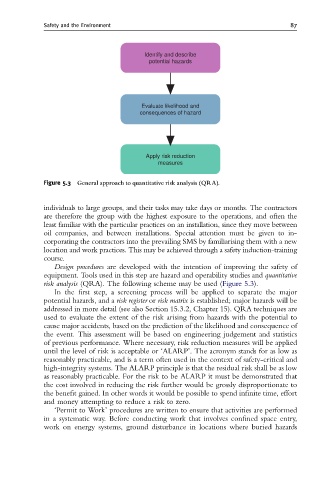

Figure 5.3 General approach to quantitative risk analysis (QRA).

individuals to large groups, and their tasks may take days or months. The contractors

are therefore the group with the highest exposure to the operations, and often the

least familiar with the particular practices on an installation, since they move between

oil companies, and between installations. Special attention must be given to in-

corporating the contractors into the prevailing SMS by familiarising them with a new

location and work practices. This may be achieved through a safety induction-training

course.

Design procedures are developed with the intention of improving the safety of

equipment. Tools used in this step are hazard and operability studies and quantitative

risk analysis (QRA). The following scheme may be used (Figure 5.3).

In the first step, a screening process will be applied to separate the major

potential hazards, and a risk register or risk matrix is established; major hazards will be

addressed in more detail (see also Section 15.3.2, Chapter 15). QRA techniques are

used to evaluate the extent of the risk arising from hazards with the potential to

cause major accidents, based on the prediction of the likelihood and consequence of

the event. This assessment will be based on engineering judgement and statistics

of previous performance. Where necessary, risk reduction measures will be applied

until the level of risk is acceptable or ‘ALARP’. The acronym stands for as low as

reasonably practicable, and is a term often used in the context of safety-critical and

high-integrity systems. The ALARP principle is that the residual risk shall be as low

as reasonably practicable. For the risk to be ALARP it must be demonstrated that

the cost involved in reducing the risk further would be grossly disproportionate to

the benefit gained. In other words it would be possible to spend infinite time, effort

and money attempting to reduce a risk to zero.

‘Permit to Work’ procedures are written to ensure that activities are performed

in a systematic way. Before conducting work that involves confined space entry,

work on energy systems, ground disturbance in locations where buried hazards