Page 309 - Hydrocarbon Exploration and Production Second Edition

P. 309

296 Facilities

gas

produced oil

fluids

slug catcher

pump

tank

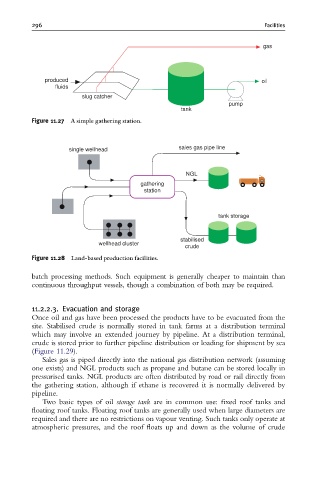

Figure 11.27 A simple gathering station.

single wellhead sales gas pipe line

NGL

gathering

station

tank storage

stabilised

wellhead cluster

crude

Figure 11.28 Land-based production facilities.

batch processing methods. Such equipment is generally cheaper to maintain than

continuous throughput vessels, though a combination of both may be required.

11.2.2.3. Evacuation and storage

Once oil and gas have been processed the products have to be evacuated from the

site. Stabilised crude is normally stored in tank farms at a distribution terminal

which may involve an extended journey by pipeline. At a distribution terminal,

crude is stored prior to further pipeline distribution or loading for shipment by sea

(Figure 11.29).

Sales gas is piped directly into the national gas distribution network (assuming

one exists) and NGL products such as propane and butane can be stored locally in

pressurised tanks. NGL products are often distributed by road or rail directly from

the gathering station, although if ethane is recovered it is normally delivered by

pipeline.

Two basic types of oil storage tank are in common use: fixed roof tanks and

floating roof tanks. Floating roof tanks are generally used when large diameters are

required and there are no restrictions on vapour venting. Such tanks only operate at

atmospheric pressures, and the roof floats up and down as the volume of crude