Page 314 - Hydrocarbon Exploration and Production Second Edition

P. 314

Surface Facilities 301

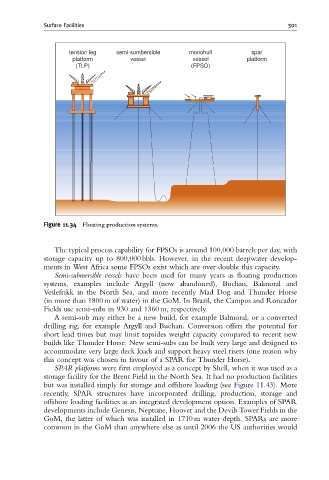

tension leg semi-sumbersible monohull spar

platform vessel vessel platform

(TLP) (FPSO)

Figure 11.34 Floating production systems.

The typical process capability for FPSOs is around 100,000 barrels per day, with

storage capacity up to 800,000 bbls. However, in the recent deepwater develop-

ments in West Africa some FPSOs exist which are over double this capacity.

Semi-submersible vessels have been used for many years as floating production

systems, examples include Argyll (now abandoned), Buchan, Balmoral and

Veslefrikk in the North Sea, and more recently Mad Dog and Thunder Horse

(in more than 1800 m of water) in the GoM. In Brazil, the Campos and Roncador

Fields use semi-subs in 930 and 1360 m, respectively.

A semi-sub may either be a new build, for example Balmoral, or a converted

drilling rig, for example Argyll and Buchan. Conversion offers the potential for

short lead times but may limit topsides weight capacity compared to recent new

builds like Thunder Horse. New semi-subs can be built very large and designed to

accommodate very large deck loads and support heavy steel risers (one reason why

this concept was chosen in favour of a SPAR for Thunder Horse).

SPAR platforms were first employed as a concept by Shell, when it was used as a

storage facility for the Brent Field in the North Sea. It had no production facilities

but was installed simply for storage and offshore loading (see Figure 11.43). More

recently, SPAR structures have incorporated drilling, production, storage and

offshore loading facilities as an integrated development option. Examples of SPAR

developments include Genesis, Neptune, Hoover and the Devils Tower Fields in the

GoM, the latter of which was installed in 1710 m water depth. SPARs are more

common in the GoM than anywhere else as until 2006 the US authorities would