Page 224 - Improving Machinery Reliability

P. 224

Machinery Reliability Audits arid Reviews 195

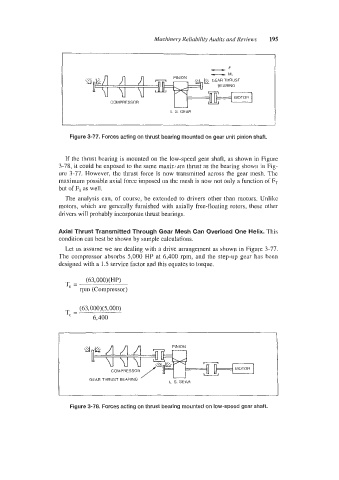

Figure 3-77. Forces acting on thrust bearing mounted on gear unit pinion shaft.

If the thrust bearing is mounted on the low-speed gear shaft, as shown in Figure

3-78, it could be exposed to the same rnaxkadin thrust as the bearing shown in Fig-

ure 3-77. However, the thrust force is now transmitted across the gear mesh. The

maximum possible axial force imposed on the mesh is now not only a function of FT

but of F, as well.

The analysis can, of course, be extended to drivers other than motors. Unlike

motors, which are generally furnished with axially free-floating rotors, these other

drivers will probably incorporate thrust bearings.

Axial Thrust Transmitted Through Gear Mesh Can Overload One Helix. This

condition can best be shown by sample calculations.

Let us assume we are dealing with a drive arrangement as shown in Figure 3-77.

The compressor absorbs 5,000 HP at 6,400 rpm, and the step-up gear has been

designed with a 1.5 service factor and this equates to torque.

(63,000)( HP)

T, =

rpm (Compressor)

(63,000)(5,000)

T, =

6,400

COMPRESSOR

’

GEAR THRUST BEARING L S GEAR

GEAR THRUST BEARING

L S GEAR

Figure 3-78. Forces acting on thrust bearing mounted on low-speed gear shaft.